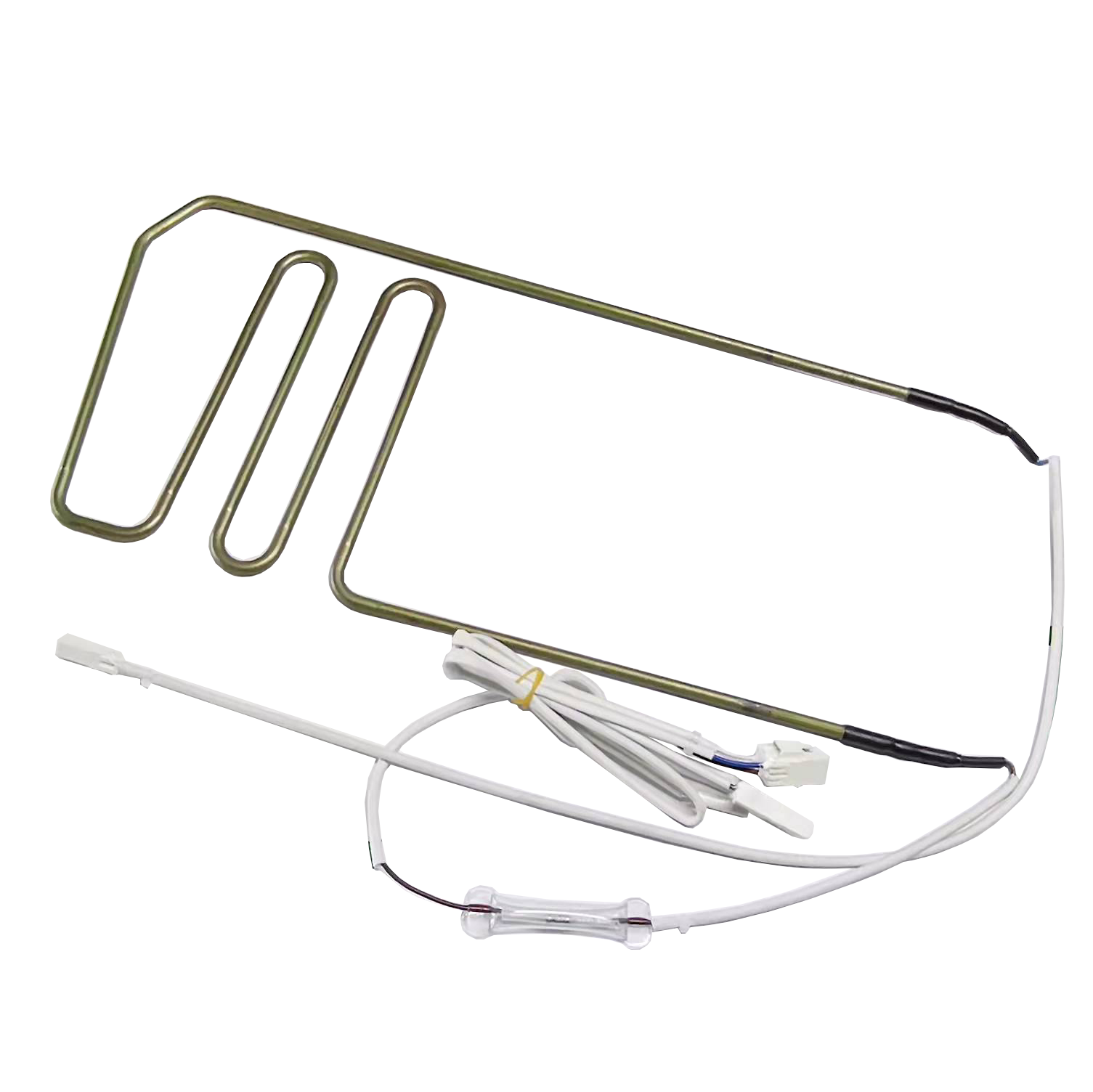

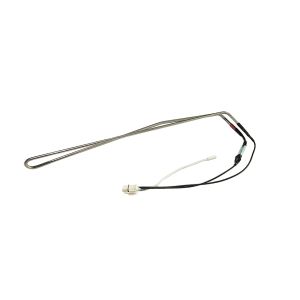

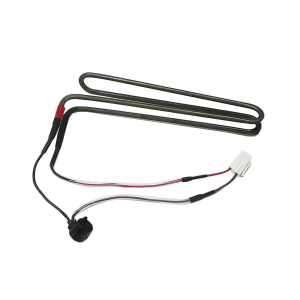

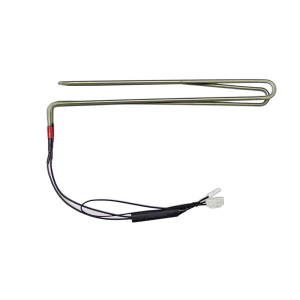

Tubular Defrost Heater BCBD202 Heating Element with NTC Sensor Refrigerator Spare Parts

Product Parameter

| Product Name | Tubular Defrost Heater BCBD202 Heating Element with NTC Sensor Refrigerator Spare Parts |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Freezer and cooling equipment

- Compressors

- Professional kitchens

- HVAC

- Outdoor use.

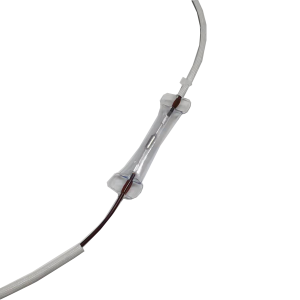

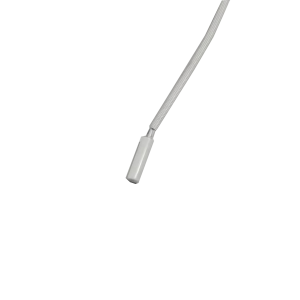

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Feature Advantages

The stainless steel cylinder is used, which is small in size, occupies less space, is easy to move, and has strong corrosion resistance. A thickened thermal insulation layer is used between the stainless steel inner tank and the stainless steel outer shell, which minimizes temperature loss, maintains temperature, and saves electricity.

Working process of refrigerator defrost heater

- The defrost system activates a defrost heater in the evaporator section at the rear of the freezer.

- This heater melts frost off of the evaporator coils and then turns off.

- During defrost there will be no running sounds, no fan noise and no compressor noise.

- Most models will defrost for approximately 25 to 45 minutes, usually once or twice a day.

- It may be heard water dripping or sizzling as it hits the heater. This is normal and helps evaporate the water before it gets to the drip pan.

- When the defrost heater is on, it is normal to see a red, yellow or orange glow from the freezer.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.