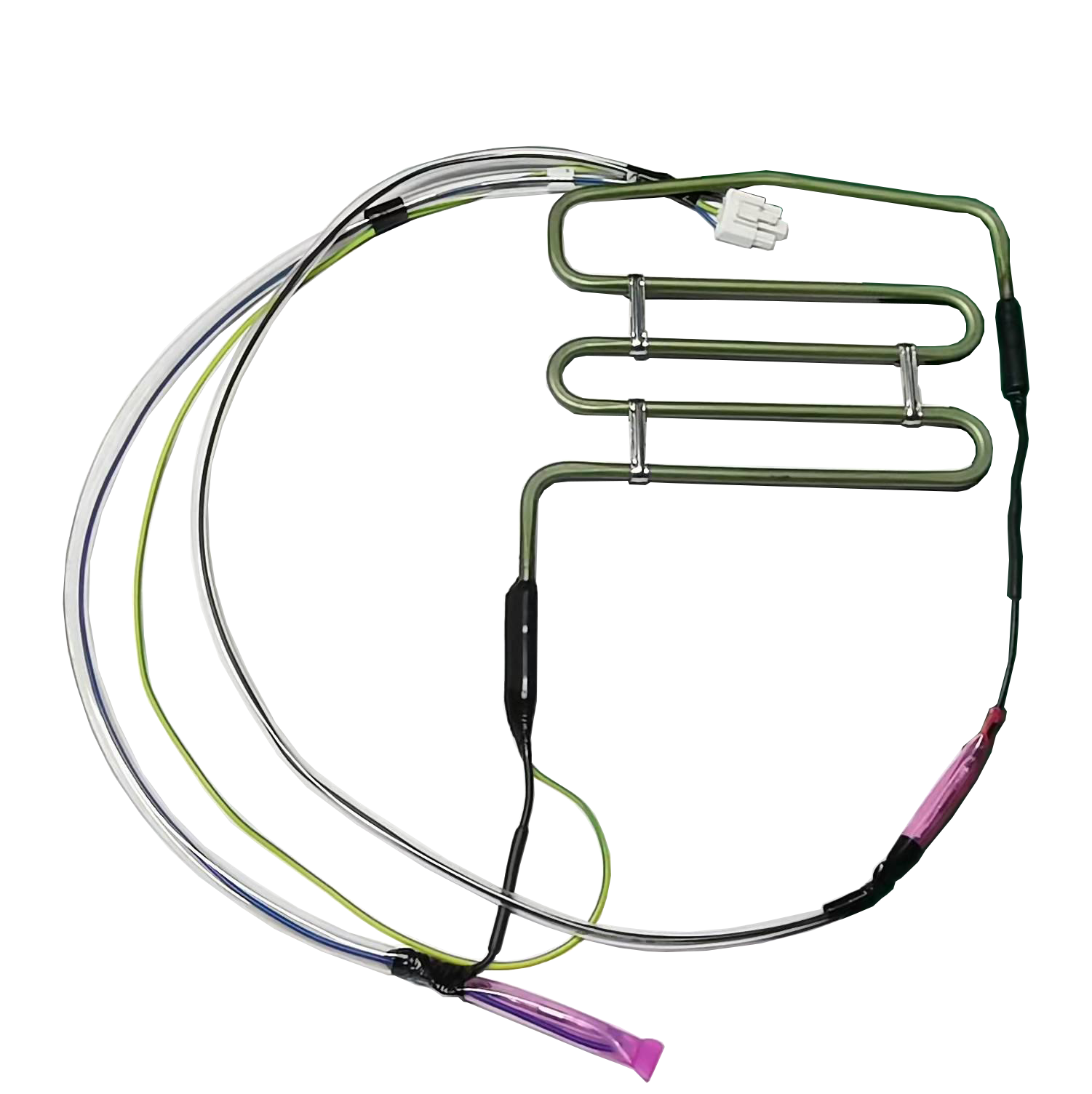

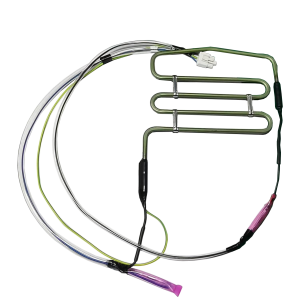

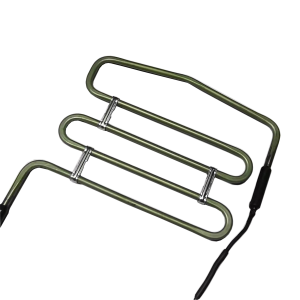

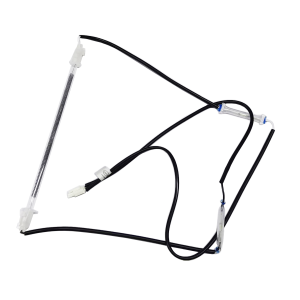

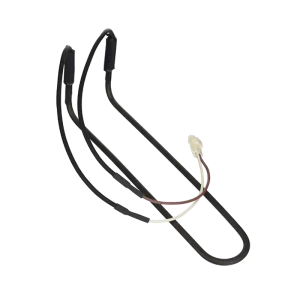

Thermal Fuse Assembly Defrost Heater Spare Parts for Refrigerator DA000730701

Product Parameter

| Product Name | Thermal Fuse Assembly Defrost Heater Spare Parts for Refrigerator DA000730701 |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

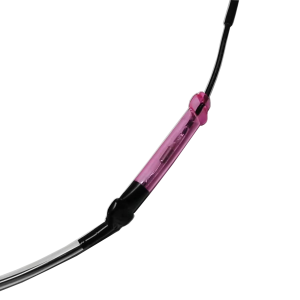

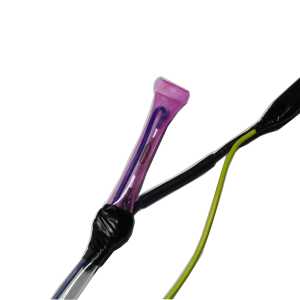

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Widely used for defrosting in refrigerators, deep freezers etc.

- These heaters can also be used in dry boxes, heaters and cookers and other middle temperature applications.

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

External metal material, can be dry burning, can be heated in water, can be heated in corrosive liquid, adapt to many external environment, a wide range of application;

The interior is filled with high temperature resistant insulating magnesium oxide powder, has the characteristics of insulation and safe use;

Strong plasticity, can be bent into various shapes;

With a high degree of controllability, can use different wiring and temperature control, with a high degree of automatic control;

Easy to use, there are some simple stainless steel electric heating tube in use only need to connect the power supply, control the opening and tube wall can be;

Easy to transport, as long as the binding post is well protected, don't worry about being knocked or damaged.

Electric Defrost

Electric defrost systems use electrical heating elements installed along or directly in the fridge’s evaporator coils. When the defrost cycle kicks in, a solenoid valve stops refrigerant from flowing to the evaporator. It then energizes the heating elements, and the evaporator uses its fans to blow hot air over the coils. This melts the ice.

Electric Defrost

Electric defrost systems use electrical heating elements installed along or directly in the fridge’s evaporator coils. When the defrost cycle kicks in, a solenoid valve stops refrigerant from flowing to the evaporator. It then energizes the heating elements, and the evaporator uses its fans to blow hot air over the coils. This melts the ice.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.