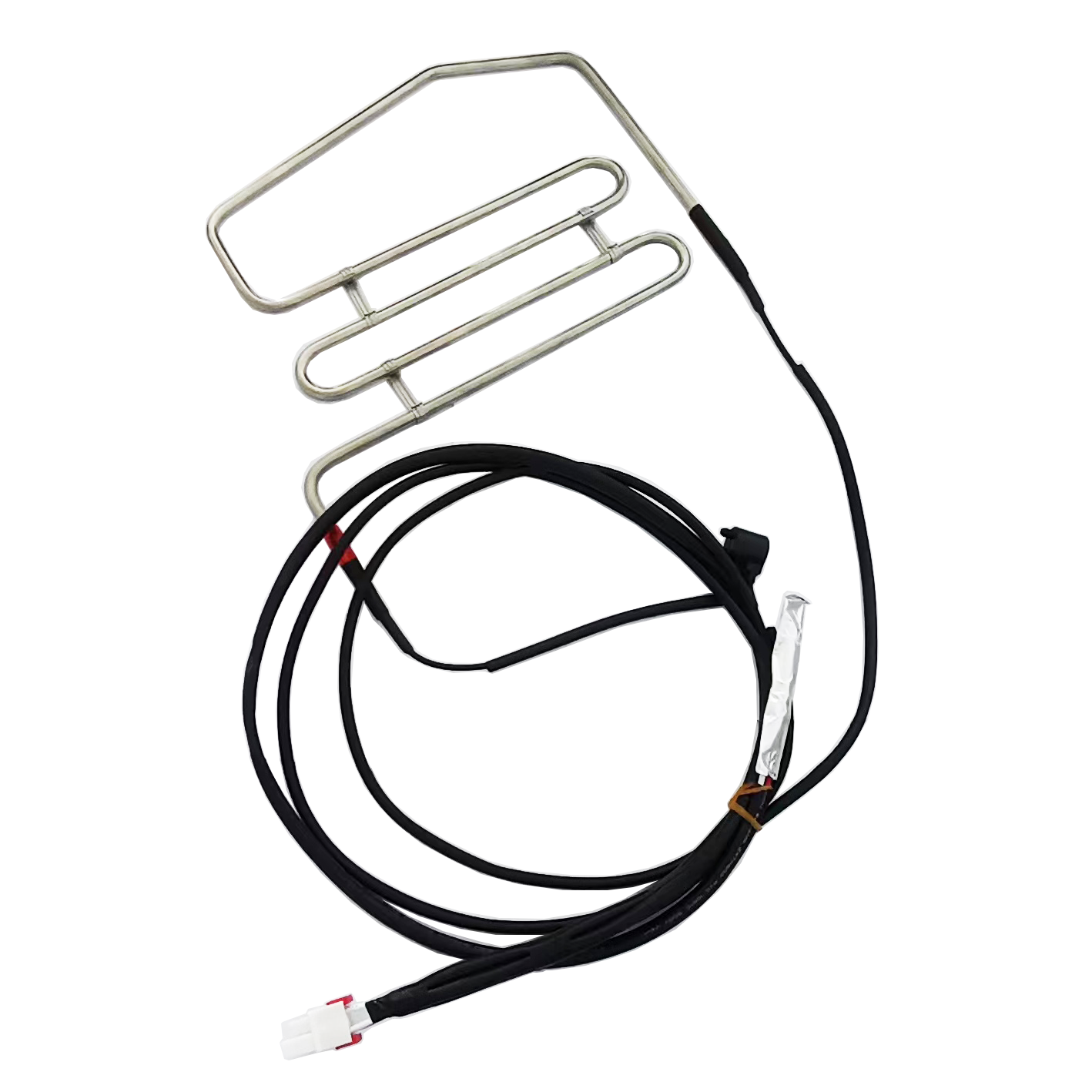

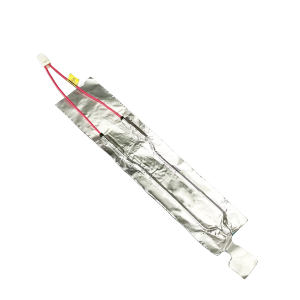

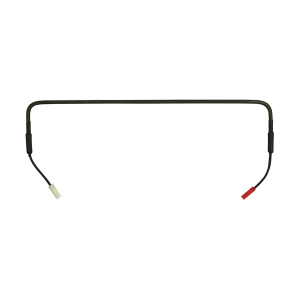

Refrigerator Spare Parts Defrosting Heater with Thermal Fuse Electronic Element Assembly

Product Parameter

| Product Name | Refrigerator Spare Parts Defrosting Heater with Thermal Fuse Electronic Element Assembly |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Wind-cooling refrigerator

- Cooler

- Air-conditioner

- Freezer

- Showcase

- Washing Machine

- Microwave Oven

- Pipe heater

- and some home appliance

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

The stainless steel cylinder is used, which is small in size, occupies less space, is easy to move, and has strong corrosion resistance. A thickened thermal insulation layer is used between the stainless steel inner tank and the stainless steel outer shell, which minimizes temperature loss, maintains temperature, and saves electricity.

How do the Auto Defrost units work?

Auto-defrost refrigeration units are designed with a fan on the compressor and an electric timer for an efficient operation. The timer controls the fan to blow the cold air in the unit, as well as the heating elements to melt any built up frost. During the defrosting process, heating elements behind the wall of the unit heat the cooling element (evaporator coil). As a result, any ice formed on the back wall melts and the water runs in the evaporator tray located on the top of the compressor. The heat of the compressor evaporates the water into the air.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.