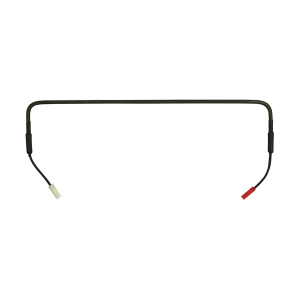

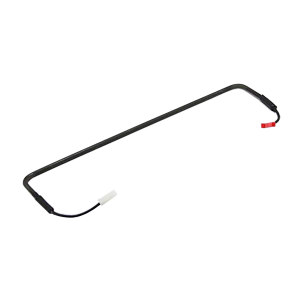

Refrigerator Evaporator Parts 242044020, 242044008 Defrost Heater kit for Frigidaire Refrigerator Electrolux

Product Parameter

| Product Name | Refrigerator Evaporator Parts 242044020, 242044008 Defrost Heater kit for Frigidaire Refrigerator Electrolux |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

It is widely used to defrosting and heat preservation for refrigerator and freezer as well as other electrical equipment. It's with rapid speed on heat and with equality, security, through thermostat, power density, insulation material, temperature switch , heat scatter conditions can be required on temperature, mainly for frost elimination in refrigerator, frozen elimination and other power heat appliance.

Defrosting Principle

When the compressor runs to a certain time, the defrosting temperature controller close to the evaporator feels the temperature of -14 degrees (or other set temperature), then the defrosting timer runs (there are large and small plastic gear CAM structure and multiple pairs of electrical contacts), when the compressor accumulates work (operation) for about 8 hours, the defrosting timer just goes to the position of connecting the defrosting. At this time, the defrosting heater (tube) is connected to the defrosting heating (the frost layer on the evaporator is heated to defrosting). When the defrosting thermostat feels positive 5 degrees (or other set temperature), the contact of the defrosting thermostat is disconnected, the defrosting thermostat (tube) stops working, and the defrosting timer starts to run for about 2 minutes due to the action of the CAM to skip the defrosting position and connect the compressor circuit for the next cycle.

Features

- High electrical strength

- Nice insulating resistance

- Anti-corrosion and ageing

- Strong overload capacity

- Little current leakage

- Good stability and reliability

- Long service life

Product Advantage

- Automatic reset for convenience

- Compact, but capable of high currents

- Temperature control and overheating protection

- Easy mounting and quick response

- Optional mounting bracket available

- UL and CSA recognized

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Production Process

A high temperature resistance wire is placed in the metal tube, and the crystalline magnesium oxide powder with good insulation and thermal conductivity is tightly filled in the gap, and the heat is transferred to the metal tube through the heating function of the heating wire, thereby heating up. The stainless steel cylinder is used, which is small in size, occupies less space, is easy to move, and has strong corrosion resistance. A thickened thermal insulation layer is used between the stainless steel inner tank and the stainless steel outer shell, which minimizes temperature loss, maintains temperature, and saves electricity.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.