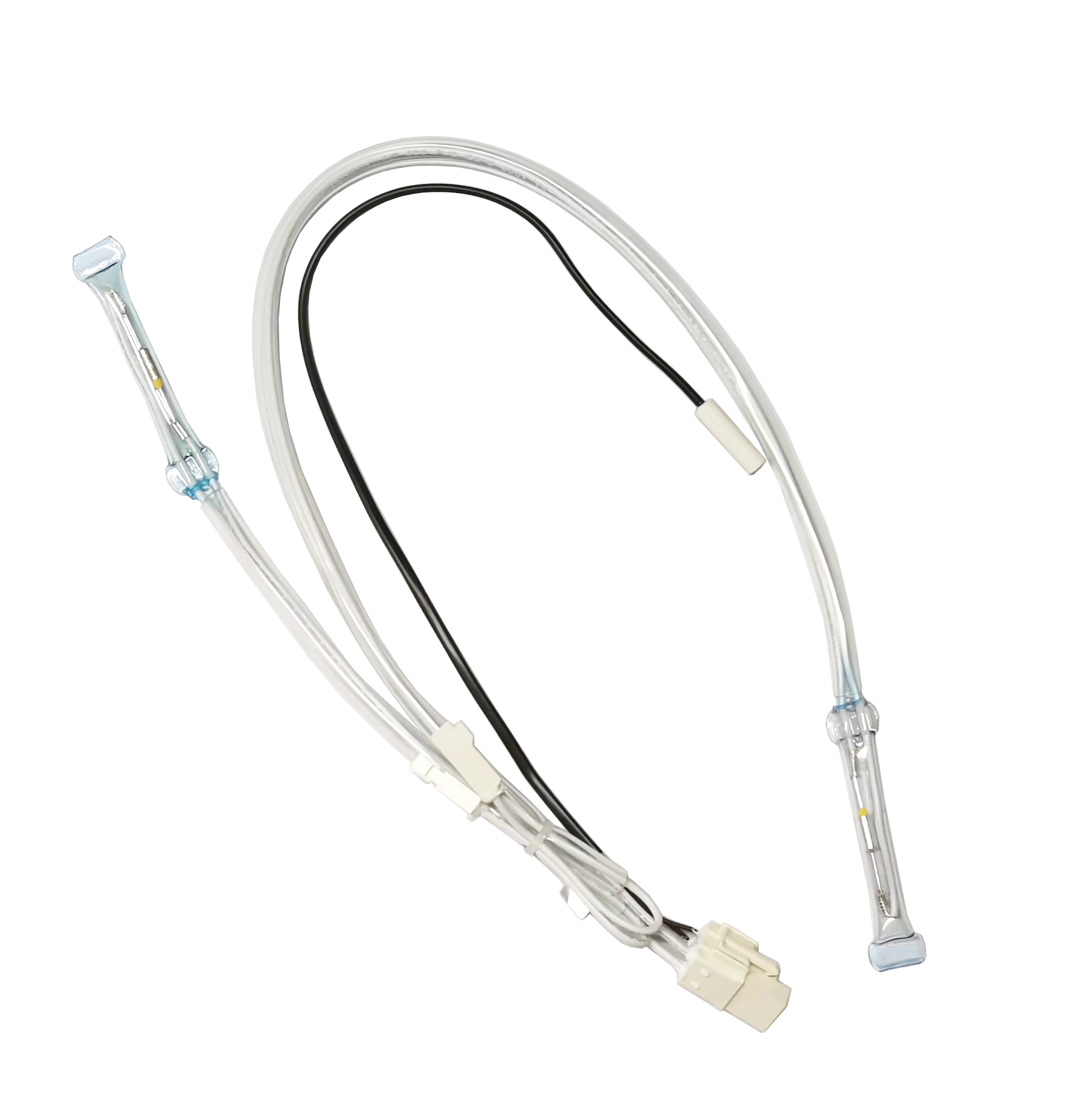

OEM/ODM Supplier Competitive Price Dryer Thermal Fuse 10K 1% 3950 Thermal Fuse 5A 250V

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for OEM/ODM Supplier Competitive Price Dryer Thermal Fuse 10K 1% 3950 Thermal Fuse 5A 250V, Seeing believes! We sincerely welcome the new customers abroad to set up business relationships and also expect to consolidate the relationships with the long-established customers.

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for China Thermal Fuse 10K and Thermal Fuse 3950, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Product Parameter

| Product Name | 15A 250V Thermal Cutoff Fuse for Refrigerator 1.D.T.0000102 Thermo Fuse Assembly |

| Use | Temperature control/Overheat protection |

| Electrical Rating | 15A / 125VAC, 7.5A / 250VAC |

| Fuse Temp | 72 or 77 Deg C |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5°C for open action(Optional +/-3 C or less) |

| Tolerance | +/-5°C for open action(Optional +/-3 C or less) |

| Protection class | IP00 |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MΩ at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Introduction

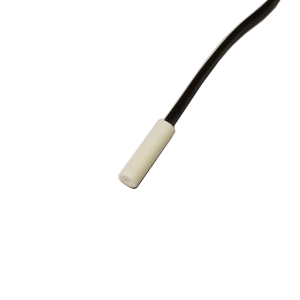

A thermal fuse or thermal cutoff is a safety device which open circuits against overheat. It detects the heat caused by the over-current due to short circuit or component breakdown.

Thermal fuses do not reset themselves when the temperature drops like a circuit breaker would. A thermal fuse must be replaced when it fails or is triggered.

Advantage

Compact,durable,and reliable by resin-sealed construction.

One shot operation.

Excellently sensitive to abomal temperature rise and high accuracy in operation.

Stable and precise operation.

Wide choice of types to suit the application.

Meet many international safety standards.

Imported quality thermal fuse

What are the characteristics of the Thermal Fuse?

Thermal fuse has the characteristics of accurate melting temperature, high withstand voltage, small size and low cost. The thermal fuse shell is marked with the rated temperature value and the rated current value, it is not difficult to identify, and it is very convenient to use. It can be widely used in electrical equipment, electric heating equipment and practical electrical appliances for overheating protection. Thermal fuse mainly has the following parameters:

①Rated temperature: Sometimes called the operating temperature or fusing temperature, it refers to the temperature at which the temperature rises to the fusing temperature at a rate of 1°C per minute under no-load conditions.

②Fusing accuracy: refers to the difference between the actual fusing temperature of the thermal fuse and the rated temperature.

③Rated current and rated voltage: Generally, the nominal current and voltage of thermal fuse have a certain margin, usually 5A and 250V.

Thermal fuse is a one-time-use protection element. Its use affects not only depends on the performance of the element itself but more importantly, on how to select and install the thermal fuse correctly. The thermal fuse is generally connected in series in the circuit when it is used. Therefore, when choosing a thermal fuse, its rated current must be greater than the current used in the circuit. Never allow the current through the thermal fuse to exceed the specified rated current. Before selecting the rated temperature of the thermal fuse, you must understand and measure the temperature difference between the temperature to be protected and the location where the planting fuse is installed.

In addition, the length of the fusing time and the availability of ventilation are also closely related to the selection of the rated temperature of the thermal fuse.

Quality assurance

All our products are 100% quality tested before leaving our facilities.We have developed our own proprietary automated testing equipment to make sure every device is tested and found to be up to reliability standards.

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for OEM/ODM Supplier Competitive Price Dryer Thermal Fuse 10K 1% 3950 Thermal Fuse 5A 250V, Seeing believes! We sincerely welcome the new customers abroad to set up business relationships and also expect to consolidate the relationships with the long-established customers.

OEM/ODM Supplier China Thermal Fuse 10K and Thermal Fuse 3950, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.