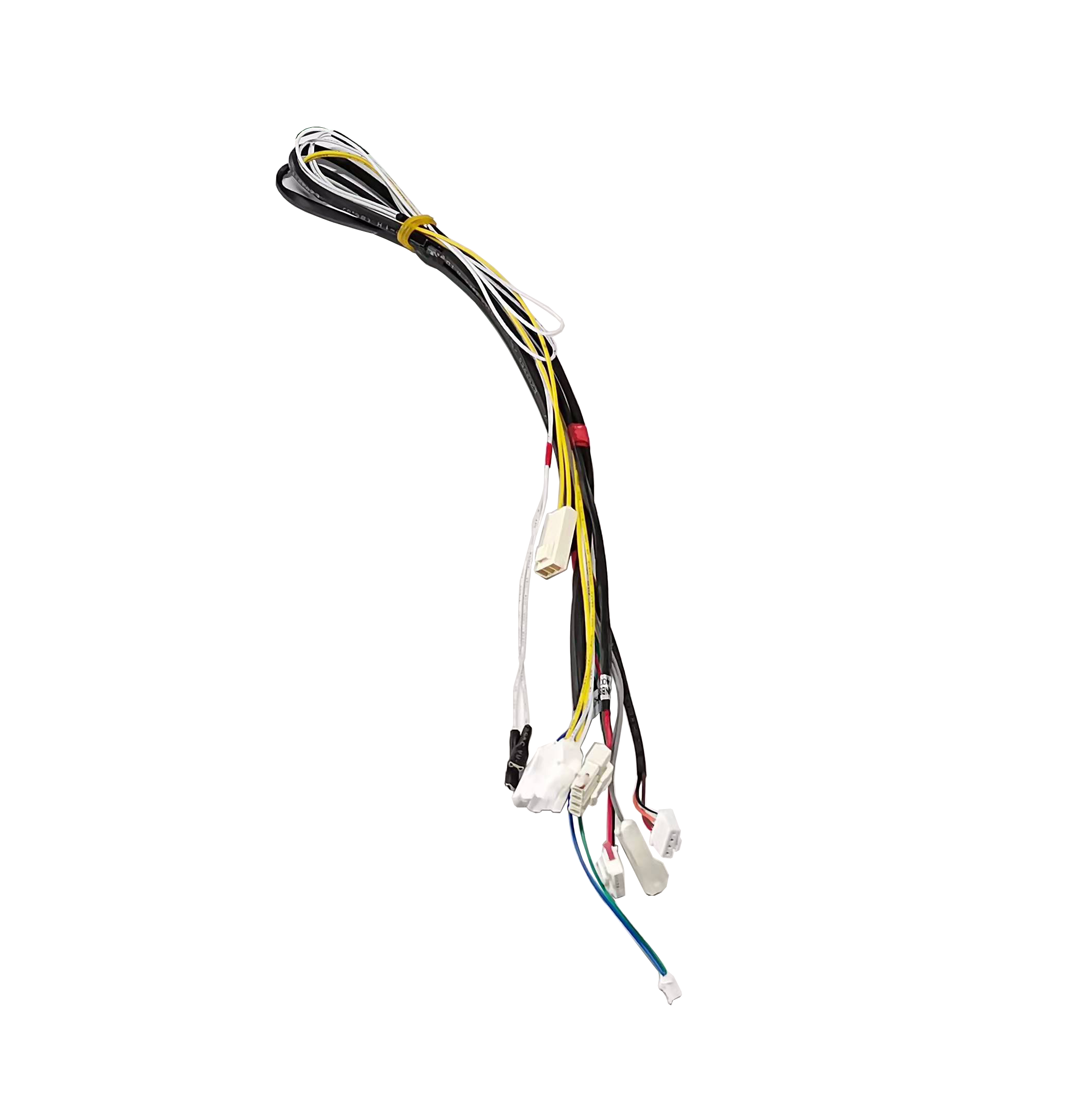

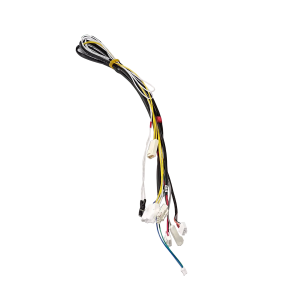

OEM Wiring Harness Connector Weak Current Wire Harness Cable Assembly DA000014001

Product Parameter

| Use | Wire harness for refrigerator, freezer, ice machine |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

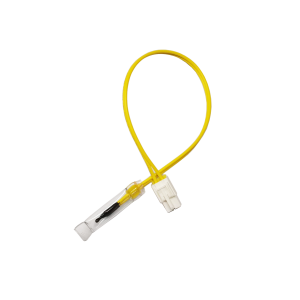

| Terminal | Molex 35745-0210, 35746-0210, 35747-0210 |

| Housing | Molex 35150-0610, 35180-0600 |

| Adhesive tape | Lead-free tape |

| Foams | 60*T0.8*L170 |

| Test | 100% test before delivery |

| Sample | Sample available |

| Terminal/Housing Type | Customized |

| Wire | Customized |

Applications

Spas, Washing machines, dryers, refrigerators, and other household appliances

Consumer and commercial electronics

Automotive equipment

Commercial and industrial machinery

Medical equipment and electronic devices

Wire Harness Design & Manufacturing Process

Simple installation processes with wire harnesses that include all of a product’s wires, cables, and subassemblies with quick connect/disconnects.

Each wire and terminal can be configured to match the exact length, dimensions, and layout of the main product it is connecting to. Wires can also be colored and labeled to streamline installation and maintenance. The manufacturing process starts with design and schematic development. It then moves to prototyping. Finally, it goes into production. Operators assemble wire harnesses on drawn out test boards which confirms precisely measured wire lengths. The board also confirms that the designed terminal and connector housings that suit the application is being used, and that cable ties and coverings are added for easy organization and transport.

Although automation plays an important role in all manufacturing processes, the complexity of the end product means that many sub-steps of assembly process must be done by hand. Wire harness cable assembly is a multifaceted process. The main steps of this process include:

Installation on the wires, terminals, and connectors on the build board

Installation of specialty components such as relays, diodes, and resistors

Installation of cable ties, tapes, and wraps for internal organization

Wire cutting and crimping for reliable terminal connection points

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.