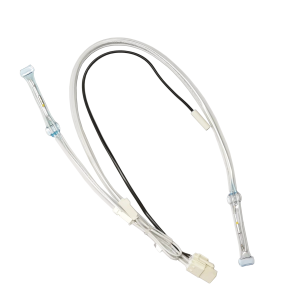

ODM Thermostat Switch Defrosting Parts Two Thermostat Assembly Thermal Protector

Product Parameter

| Product Name | ODM Thermostat Switch Defrosting Parts Two Thermostat Assembly Thermal Protector |

| Use | Temperature control/Overheat protection |

| Reset type | Automatic |

| Base material | resist heat resin base |

| Electrical Ratings | 15A / 125VAC, 7.5A / 250VAC |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5 C for open action(Optional +/-3 C or less) |

| Protection class | IP00 |

| Contact material | Silver |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MW at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Diameter of bimetal disc | 12.8mm(1/2″) |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- White goods

- Electric heaters

- Automotive seat heaters

- Rice Cooker

- Dish Dryer

- Boiler

- Fire Apparatus

- Water Heaters

- Oven

- Infrared Heater

- Dehumidifier

- Coffee Pot

- Water purifiers

- Fan Heater

- Bidet

- Microwave Range

- Other Small Appliances

Features

- Slimmest construction

- Dual contacts structure

- High reliability for contact resistance

- Safety design according to IEC standard

- Environmental friendly towards RoHS, REACH

- Automatic resettable

- Accurate and quick switching snap action

- Available horizontal terminal direction

Working Principle

1.The working principle of the snap action bimetallic thermostat is that the temperature sensitive element bimetal disc is pre-formed at a certain temperature, when the ambient temperature changes, the bending degree of the disc will change. When bending to a certain degree, the circuit is switched on (or disconnected), so that the cooling (or heating) equipment works.

2.Thermal bimetal is composed of two or more kinds of different expansion coefficient of metal or alloy along the entire contact surface firmly combined together with the shape changes with temperature composite functional materials.

3.In the thermal bimetallic component alloy, the component alloy layer with a higher expansion coefficient is generally called the active layer or high expansion layer (HES). The component alloy layer with low expansion coefficient is called passive layer or low expansion layer (LES). Adding an intermediate layer of different thickness between the active layer and the passive layer as a conductive layer, generally including pure Ni, pure Cu and zirconium copper, etc., mainly used to control the resistivity of the thermal bimetal can obtain a series of resistive thermal bimetals with basically the same thermal sensitive properties and different resistivity.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.