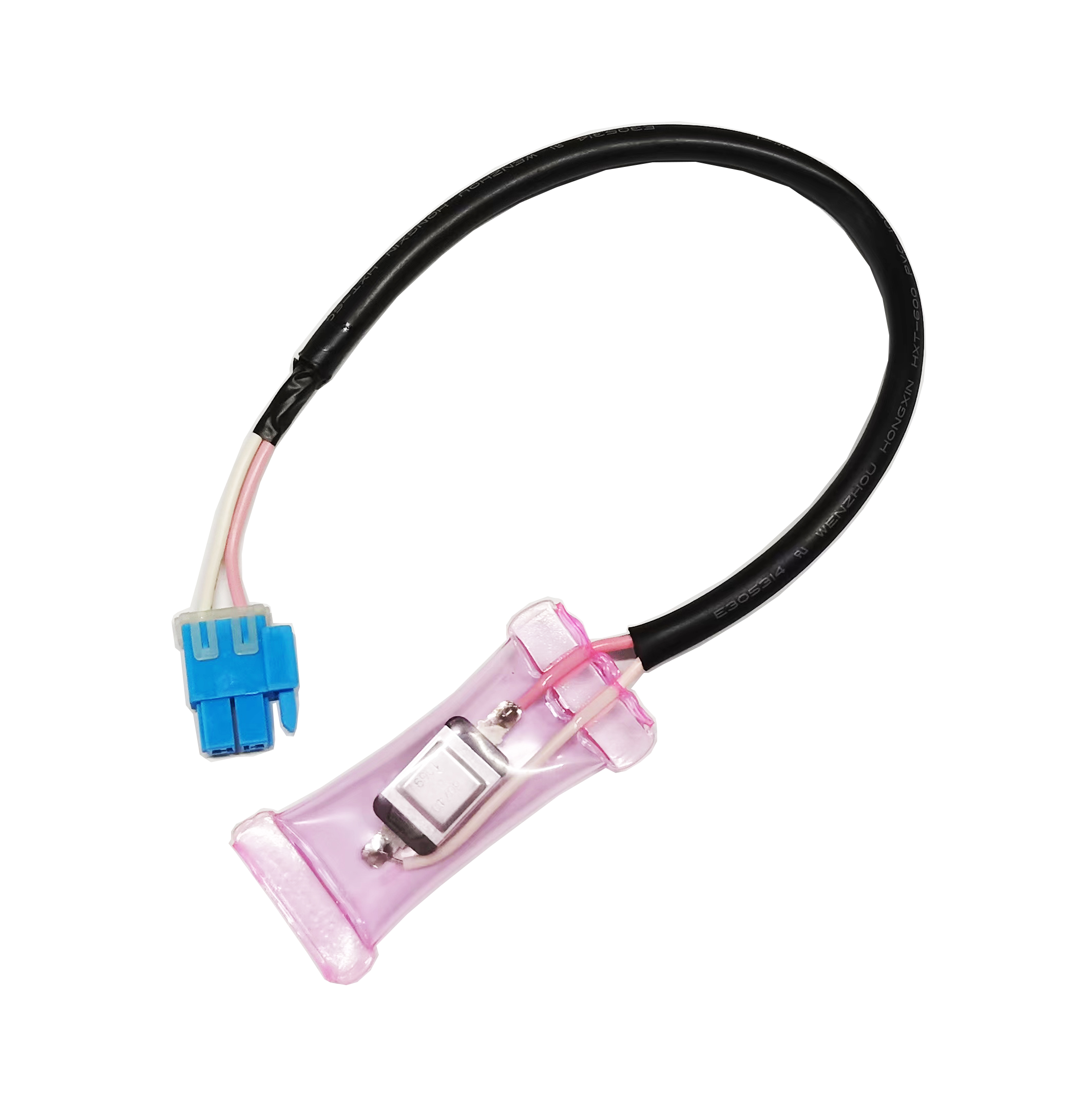

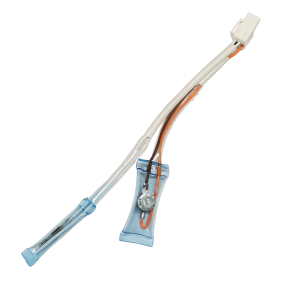

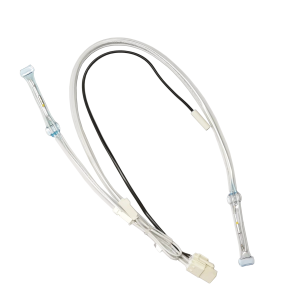

ODM Low Temperature Thermostat Switch Fridge Bimetal Thermal Fuse Assembly DA47-10160J

Product Parameter

| Product Name | ODM Low Temperature Thermostat Switch Fridge Bimetal Thermal Fuse Assembly DA47-10160J |

| Use | Temperature control/Overheat protection |

| Reset type | Automatic |

| Base material | resist heat resin base |

| Electrical Ratings | 15A / 125VAC, 7.5A / 250VAC |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5 C for open action(Optional +/-3 C or less) |

| Protection class | IP00 |

| Contact material | Silver |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MW at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Diameter of bimetal disc | 12.8mm(1/2″) |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

Removing frost and protecting the frozen rupture in the cold storage or freezing systems.

Used for sensing and Instrumentation, HVAC System, Consumer Electronics, and Others.

Features

• Easy to install at the small or narrow space

• Slim shape small size with high contacting capacitance

• Available waterproof and dustproof types with welding vinyl tube on the parts

• Terminals, caps brackets or contacts can be customized

• 100% Temp&Dielectric tested

• Life Cycle 100,000 cycle.

Feature Advantage

Wide variety of installation fixtures and probes are available to suit customer needs.

Small size and fast response.

Long-term stability and reliability

Excellent tolerance and inter changeability

Lead wires can be terminated with customer-specified terminals or connectors

Temperature Sensing & Response

Many factors can affect how a thermostat senses and responds to temperature changes in an

application. Typical factors include, but are not limited to, the following:

• Mass of the thermostat

• Switch head ambient temperature. The“switch head”is the plastic or ceramic body and terminal area of the thermostat. It does not include the sensing area.

• Rate of temperature rise and fall in the application

• Intimacy of contact between the thermostat sensing surface and the surface it is mounted on

• Heat transfer by conduction, convection or radiation

It is important to understand that the temperature of the thermostat will typically change more

slowly than or lag the temperature it is trying to sense. The impact of the factors mentioned in the previous paragraph will determine the magnitude of the thermal lag. Thermal lag will directly affect determination of thermostat calibration to regulate or limit temperature for a particular application.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.