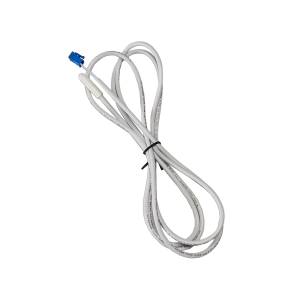

NTC Temperature Sensor for Refrigerator Factory Price Thermistor Resistor 190BC

Product Parameter

| Use | Temperature Control |

| Reset Type | Automatic |

| Probe Material | Stainless Steel |

| Operating Temperature | -40°C~120°C (dependent on wire rating) |

| Ohmic Resistance | 10K +/-1% to Temp of 25 deg C |

| Beta | (25C/85C) 3977 +/-1.5%(3918-4016k) |

| Electric Strength | 1250 VAC/60sec/0.1mA |

| Insulation Resistance | 500 VDC/60sec/100M W |

| Resistance Between Terminals | Less than 100m W |

| Extraction Force between Wire and Sensor Shell | 5Kgf/60s |

| Approvals | UL/ TUV/ VDE/ CQC |

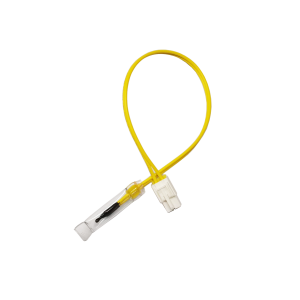

| Terminal/Housing type | Customized |

| Wire | Customized |

NTC Probe Encapsulation Characteristics

NTC temperature sensor is a kind of temperature-sensitive semiconductor ceramic element. It has the characteristics of fast response, high precision, good stability and low cost. It is widely used in various temperature-related occasions.

The commonly used encapsulation methods include epoxy resin encapsulation, diode encapsulation, single end glass encapsulation, film thermistor, etc.

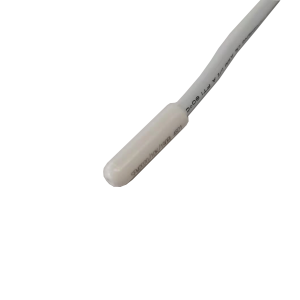

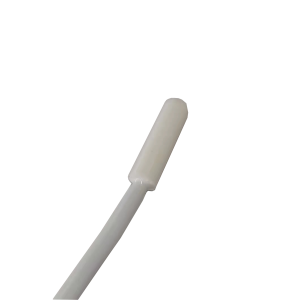

The encapsulation process of temperature sensor with epoxy resin encapsulation is relatively simple. Generally, the insulating wire (such as PVC, Teflon wire, etc.) is used to weld thermistor chips, and then the NTC temperature sensor is packaged with epoxy resin. The minimum size of the head can be 2.0mm.

Several Common Encapsulation Forms for Temperature Sensors

1. Common metal straight tube encapsulation temperature sensor

The encapsulation form of this temperature sensor is often used in simple installation environment. According to the measured temperature range, it is divided into high temperature temperature sensor, medium temperature or ordinary temperature sensor and low temperature sensor. The high temperature measurement temperature can reach the long-term working temperature of 400℃, and the low temperature range can reach -200℃.

2. Threaded encapsulation temperature sensor

The thread temperature sensor is often used in the environment where the temperature sensor needs to be fixed. The thread used is basically standard thread. The size of thread is selected according to the installation position of the temperature sensor.

3. Flange mounted large temperature sensor

This temperature sensor is often used in large pipes or equipment.

4. Wall-mounted temperature sensor

Wall-mounted temperature sensor is often used indoors or in the cabinet body, simple installation, with a display screen can also be read on site.

5. Temperature sensor with various plugs at the end

Temperature sensor for easy installation can be installed at the end of a variety of plugs, free of wiring troubles, plug and play.

Craft Advantage

We operate additional cleavage for the wire and pipe parts to reduce the flow of epoxy resin along the line and reduce the height of the epoxy. Avoid gaps and breakage bending of wires during assembly.

Cleft area effectively reduce the gap at the bottom of the wire and reduce the immersion of water under long-term conditions.Increase the reliability of the product.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.