In order to control the cooling temperature of refrigeration equipment such as refrigerators and air conditioners and the heating temperature of electric heating devices, thermostats are installed on both refrigeration equipment and electric heating devices.

1. Classification of thermostats

(1) Classification by control method

Thermostats can be divided into two types: mechanical type and electronic type according to the control method.The mechanical thermostats detect the temperature through the temperature sensing capsule,and then controls the compressor power supply system through the mechanical system, thereby realizing temperature control;the electronic thermostats detect the temperature through a negative temperature coefficient(NTC) thermistor, and then controls the power supply system of the compressor through a relay or a thyristor, thereby realizing temperature control.

(2) Classification by material composition

Thermostats can be divided into bimetal thermostats, refrigerant thermostats, magnetic thermostats, thermocouple thermostats and electronic thermostats according to their material composition.

(3) Classified by function

Thermostats can be divided into refrigerator thermostats, air conditioner thermostats, rice cooker thermostats, electric water heater thermostats, shower thermostats, microwave oven thermostats, barbecue oven thermostats, etc according to fuction.

(4) Classification according to how the contacts work

Thermostats can be divided into normally open contact type and normally closed contact type according to the working mode of the contacts.

2. Identification and test of bimetal thermostats

Bimetal thermostat is also called temperature control switch and its function is mainly to control the heating temperature of the electric heating device.Pictures of some common bimetal thermostats are as follows.

(1) Composition and principle of bimetal thermostat

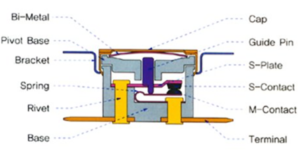

Bimetal thermostat consists of thermal sensor,bimetal,pin,contact,contact reed,etc,as shown below.After the electric heating device is energized, it starts to heat, and when the temperature detected by the thermostat is low, the bimetallic sheet bends upwards without touching the pin, and the contact is closed under the action of the contact reed. With the continuous heating, after the temperature detected by the thermostat reaches the set value, the bimetal is deformed and pressed down, and the contact reed is bent downward through the pin, causing the contact to be released, and the heater stops working due to no power supply. , the electric heating device enters the heat preservation state. With the extension of the holding time, the temperature begins to drop. After the thermostat detects it, the bimetal is reset, the contact is pulled in under the action of the reed, and the power supply circuit of the heater is turned on again to start heating. By repeating the above process, automatic temperature control is achieved.

(2) Test of bimetal thermostat

As shown below,When it is not heated, use the “R×1″ key of the multimeter to measure the resistance value between the terminals of the bimetal thermostat. If the resistance value is infinite, it means that the circuit is open; and the temperature it detects reaches the nominal value,the resistance value cannot be infinite and it is still 0, which means the contacts inside are sticking.

Post time: Jul-28-2022