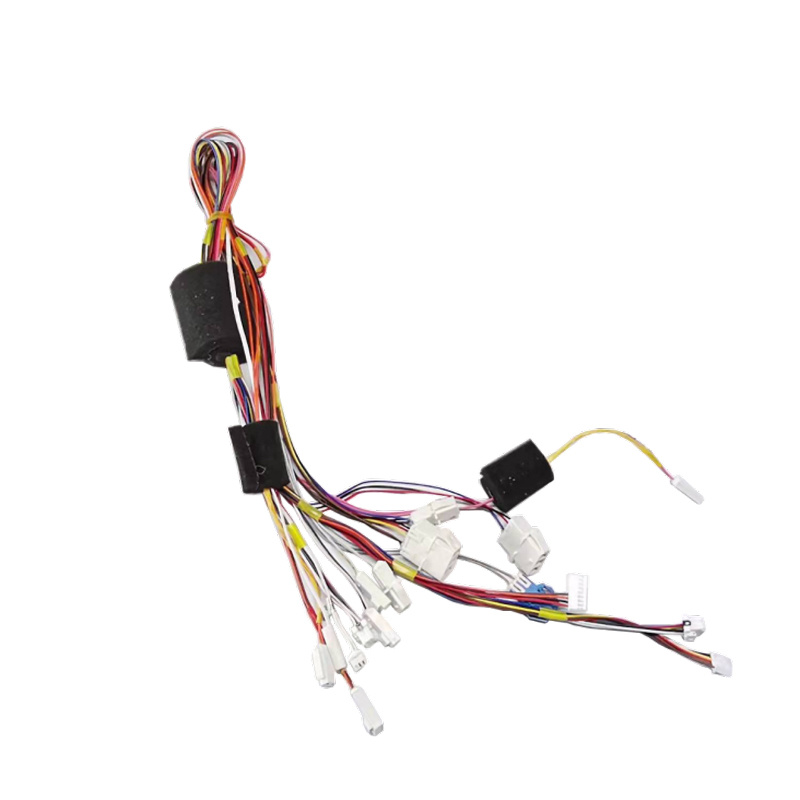

Hot New Products Cooling Fan Wiring Harness - Customized Harness Wire Auto Electrical Wiring Harness Cable Assembly for Home Appliance – Sunfull Hanbecthistem

Hot New Products Cooling Fan Wiring Harness - Customized Harness Wire Auto Electrical Wiring Harness Cable Assembly for Home Appliance – Sunfull Hanbecthistem Detail:

Description

| Product Name | Customized Harness Wire Auto Electrical Wiring Harness Cable Assembly for Home Appliance |

| Use | Wire harness for refrigerator, freezer, ice machine |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Terminal | Molex 35745-0210, 35746-0210, 35747-0210 |

| Housing | Molex 35150-0610, 35180-0600 |

| Adhesive tape | Lead-free tape |

| Foams | 60*T0.8*L170 |

| Test | 100% test before delivery |

| Sample | Sample available |

| Terminal/Housing Type | Customized |

| Wire | Customized |

Applications

Typical Applications:

- Refrigerator

- Freezer

- Ice Machine

- Electrical Stove

- Washing Machine

Why Are Wire Harnesses Assembled Manually?

Wire harness assembly process is one of the few remaining manufacturing processes that is more efficiently done by hand, rather than automation. This is due to the variety of processes that are involved in the assembly. These manual processes include:

Installing terminated wires in various lengths

Routing wires and cables through sleeves and conduits

Taping breakouts

Conducting multiple crimps

Binding the components with tape, clamps or cable ties

Because of the difficulty involved in automating these processes, manual production continues to be more cost-effective, especially with small batch sizes. This is also why harness production takes longer than other types of cable assemblies. Production can take anywhere from a few days to several weeks. The more complicated the design, the longer production time is required.

However, there are certain portions of pre-production that can benefit from automation. These include:

Using an automated machine to cut and strip the ends of individual wires

Crimping terminals on one or both sides of the wire

Plugging wires pre-fitted with terminals into connector housings

Soldering wire ends

Twisting wires

Product detail pictures:

Related Product Guide:

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Hot New Products Cooling Fan Wiring Harness - Customized Harness Wire Auto Electrical Wiring Harness Cable Assembly for Home Appliance – Sunfull Hanbecthistem , The product will supply to all over the world, such as: Malta, Suriname, Malawi, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!