ELTH 1/2″ Refrigerator Defrosting Bimetallic Thermostat Switches Type 261

Product Parameter

| Product Name | ELTH 1/2" Refrigerator Defrosting Bimetallic Thermostat Switches Type 261 |

| Use | Temperature control/Overheat protection |

| Reset type | Automatic |

| Base material | resist heat resin base |

| Electrical Ratings | 15A / 125VAC, 7.5A / 250VAC |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5 C for open action(Optional +/-3 C or less) |

| Protection class | IP00 |

| Contact material | Silver |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MW at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Diameter of bimetal disc | 12.8mm(1/2″) |

| Approvals | UL/ TUV/ VDE/ CQC |

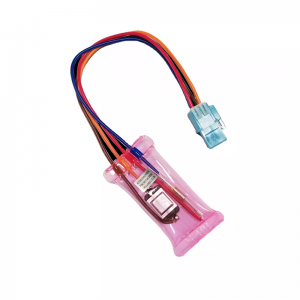

| Terminal type | Customized |

| Cover/Bracket | Customized |

Typical Applications

- White goods

- Electric heaters

- Automotive seat heaters

- Rice Cooker

- Dish Dryer

- Boiler

- Fire Apparatus

- Water Heaters

- Oven

- Infrared Heater

- Dehumidifier

- Coffee Pot

- Water purifiers

- Fan Heater

- Bidet

- Microwave Range

- Other Small Appliances

The Installation Position of Defrost Thermostat

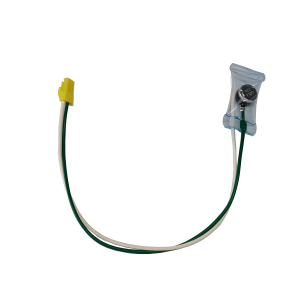

Some defrost systems use a thermostat (a bi-metal switch) to prevent the defrost heater from overheating. The switch is normally closed. During a defrost cycle, the defrost heater causes the metal alloy in the switch to warm and as it does it curls back and breaks the circuit. As the metal cools, it makes a circuit again and the defrost heater starts heating again (as long as the defrost timer is in the defrost cycle).

The defrost thermostat is located near the defrost heater and is wired in series. It is usually located at the back of a side by side freezer or under the floor of a top freezer. It will be necessary to remove obstructions such as the contents of the freezer, freezer shelves, icemaker and the inside rear or bottom panel of the freezer.

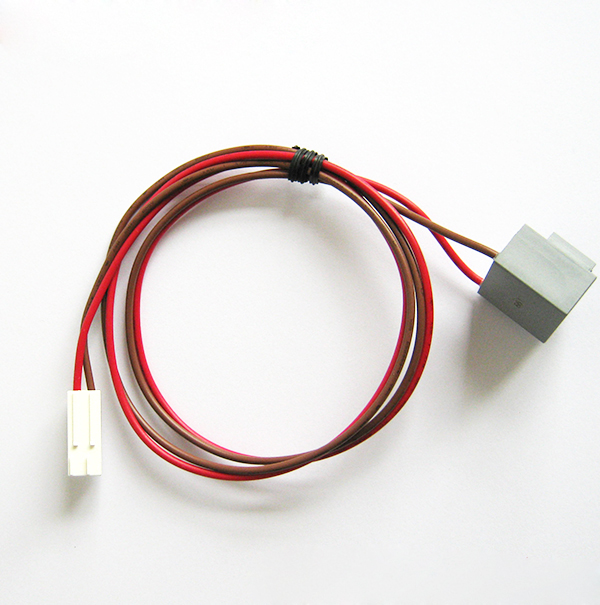

The thermostat is connected by two wires. The wires are connected with slip on connectors or a wiring harness. Firmly pull the connectors or harness off of the terminals (do not pull on the wire). It may need to use a pair of needle-nose pliers to remove the connectors. Inspect the connectors and the terminals for corrosion. If the connectors are corroded they should be replaced.

Craft Advantage

Slimmest construction

Dual contacts structure

High reliability for contact resistance

Safety design according to IEC standard

Environmental friendly towards RoHS,REACH

Automatic resettable

Accurate and quick switching snap action

Available horizontal terminal direction

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.