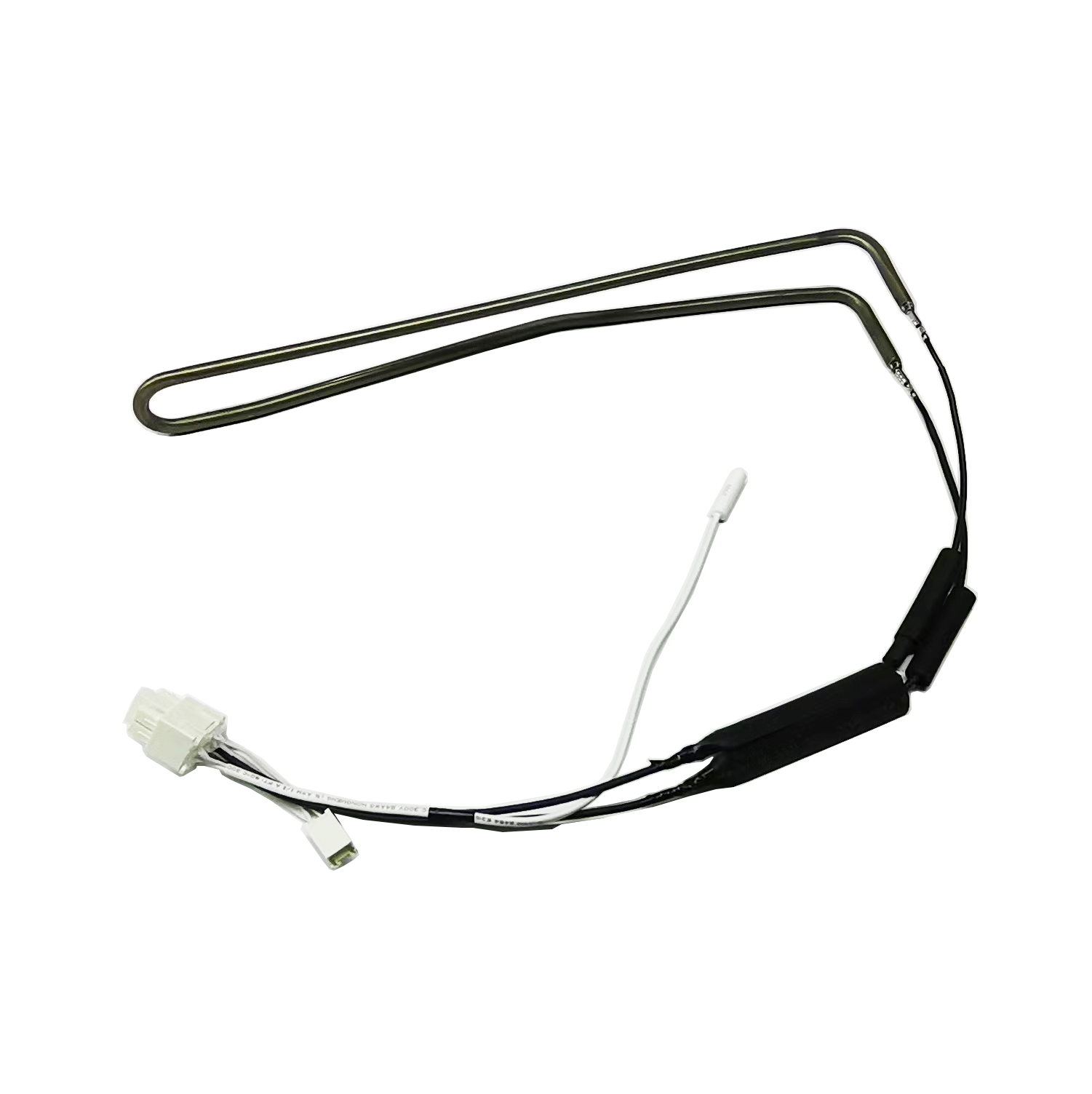

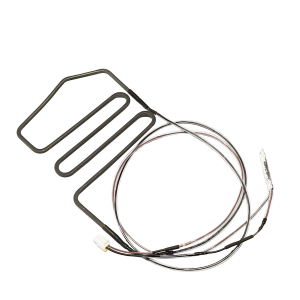

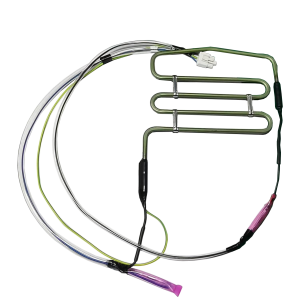

Electronic Heating Element Tube for Refrigerator Heat Exchanger Steel Defrost Heater BCBD202

Product Parameter

| Product Name | Electronic Heating Element Tube for Refrigerator Heat Exchanger Steel Defrost Heater BCBD202 |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

It is widely used to defrosting and heat preservation for refrigerator and freezer as well as other electrical equipment. It's with rapid speed on heat and with equality, security, through thermostat, power density, insulation material, temperature switch , heat scatter conditions can be required on temperature, mainly for frost elimination in refrigerator, frozen elimination and other power heat appliance.

Electric Defrost

Electric defrost systems use electrical heating elements installed along or directly in the fridge’s evaporator coils. When the defrost cycle kicks in, a solenoid valve stops refrigerant from flowing to the evaporator. It then energizes the heating elements, and the evaporator uses its fans to blow hot air over the coils. This melts the ice.

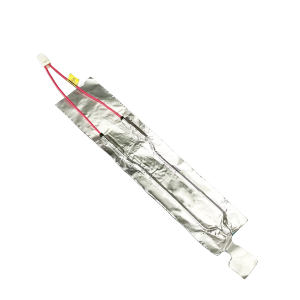

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

- High electrical strength

- Nice insulating resistance

- Anti-corrosion and ageing

- Strong overload capacity

- Little current leakage

- Good stability and reliability

- Long service life

Custom Production

- Custom cold sections

- Elements available in copper, incoloy or stainless steel

- Factory installed wire terminations

- Inline fusing

- Grounding wire welded to element sheath

- Single ended or double ended molded waterproof terminals

- Bimetal automatic limit control and/or fusible link molded in a waterproof mold for sheath temperature sensing.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.