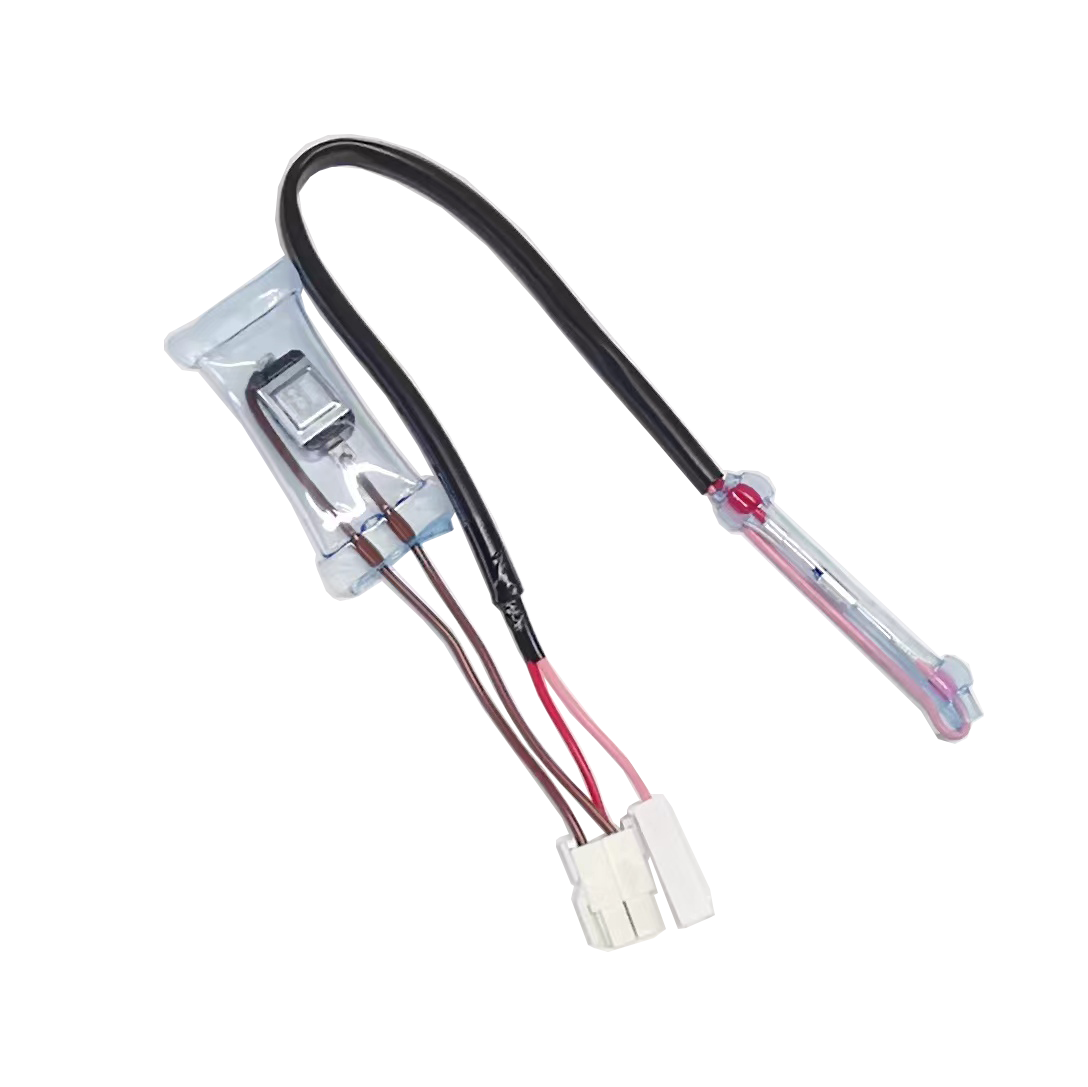

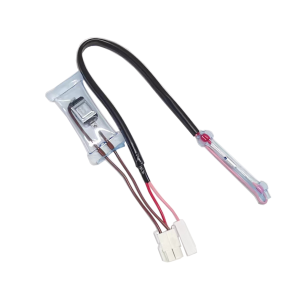

Defrost Thermostat Fuse for Refrigerator Bimetallic Thermostat & Thermal Fuse Assembly

Product Parameter

| Product Name | Defrost Thermostat Fuse for Refrigerator Bimetallic Thermostat & Thermal Fuse Assembly |

| Use | Temperature control/Overheat protection |

| Reset type | Automatic |

| Base material | Resist heat resin base |

| Electrical Rating | 15A / 125VAC, 10A / 240VAC, 7.5A / 250VAC |

| Operating Temperature | -20°C~150°C |

| Tolerance | +/-5°C for open action(Optional +/-3 C or less) |

| Protection class | IP68 |

| Contact material | Double Solid Silver |

| Dielectric Strength | AC 1500V for 1 minute or AC 1800V for 1 second |

| Insulation Resistance | More than 100MΩ at DC 500V by Mega Ohm tester |

| Resistance Between Terminals | Less than 100mW |

| Diameter of bimetal disc | Φ12.8mm(1/2″) |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications:

Refrigerators, Show Case (cold storage, freezing, thermal insulation), Ice Maker, etc

Function:

Automatic temperature control for removing frost and for protecting the frozen rupture in the cold storage or freezing

Features

- Easy to install at the small or narrow space

- Slim shape

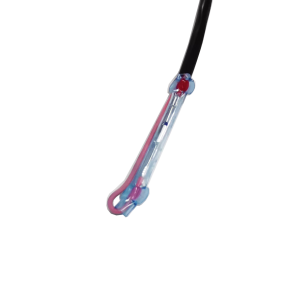

- Small size with high contacting capacitance

- Available waterproof and dustproof types with welding vinyl tube on the parts

- Any requirement on the terminals, caps, brackets or contacts are acceptable

Feature Advantage

Wide variety of installation fixtures and probes are available to suit customer needs.

Small size and fast response.

Long-term stability and reliability

Excellent tolerance and inter changeability

Lead wires can be terminated with customer-specified terminals or connectors

Craft Advantage

In any refrigeration process or application the heat being transferred can cause condensation to form on the evaporator. If the temperature is low enough the gathered condensation will freeze, leaving a frost deposit on the evaporator. The frost will subsequently act as insulation on the evaporator pipes and reduce the efficiency of heat transfer, which in turn means the system needs to work harder to cool the environment sufficiently, or that the fridge cannot reach the setpoint at all.

This has repercussions on either the product not being kept or cooled to the correct temperature, which can increase instances of faulty product, or it means more energy is expended trying to maintain the correct temperature, increasing running costs. In either case there is a loss to the business due to wastage or higher overheads.

Defrost thermostats combat this by periodically melting any frost forming on the evaporator and allowing the water to drain away, keeping the moisture level in the environment as low as possible.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.