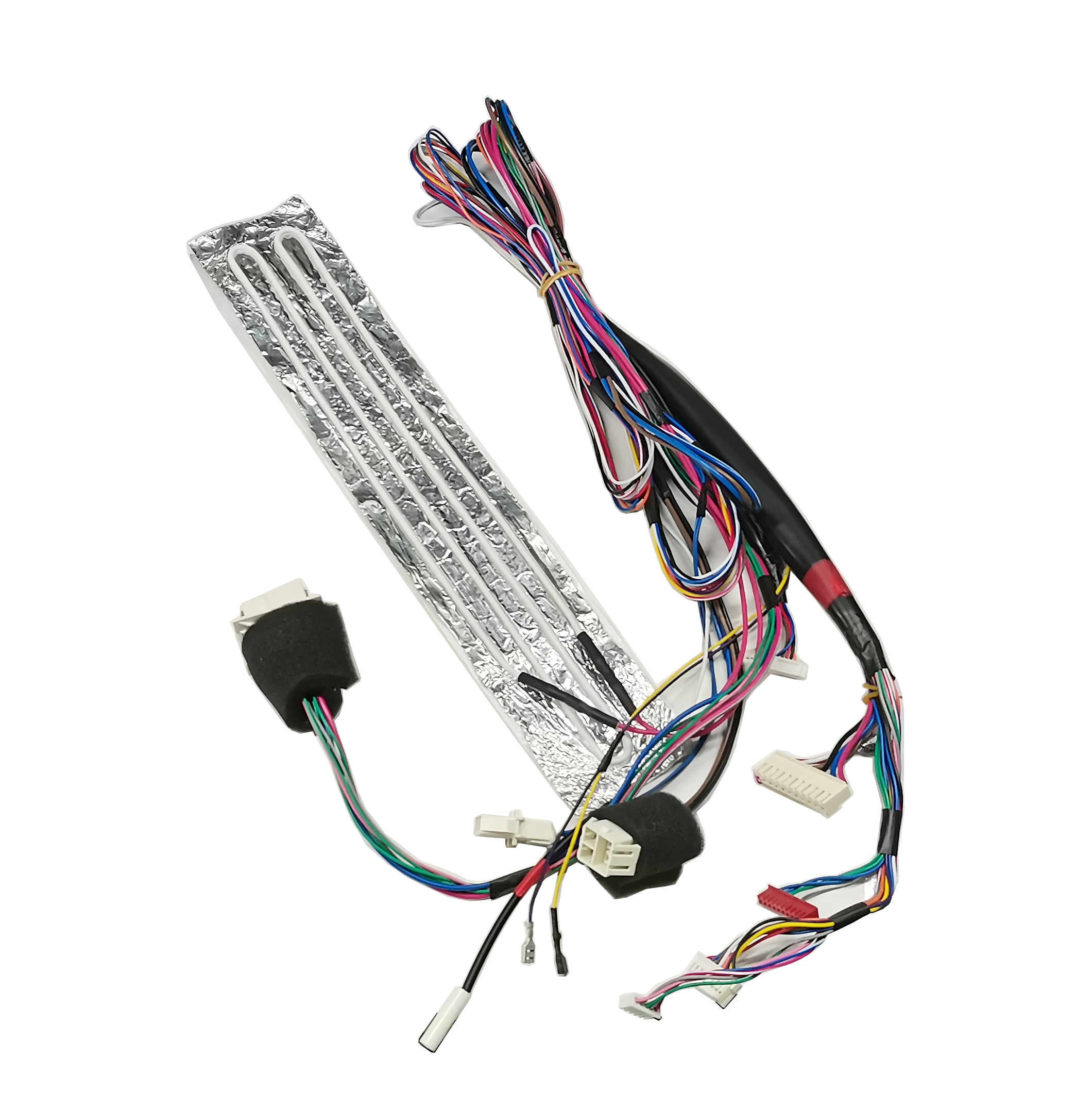

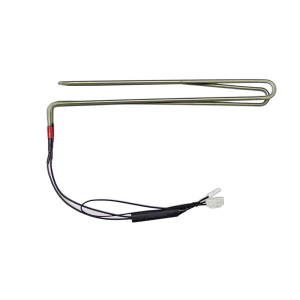

3009900427 Wire Harness Cable with Aluminum Foil Heater for Home Appliance BCD-216W

Product Parameter

| Use | Wire harness for refrigerator, freezer, ice machine |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Wire | Customized |

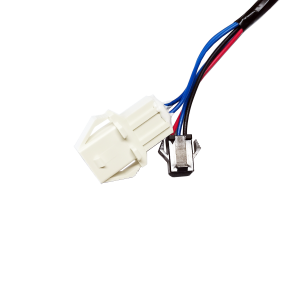

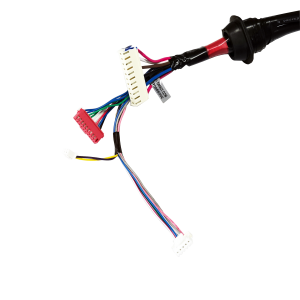

| Terminal | Molex 35745-0210, 35746-0210, 35747-0210 |

| Housing | Molex 35150-0610, 35180-0600 |

| Adhesive tape | Lead-free tape |

| Foams | 60*T0.8*L170 |

| Test | 100% test before delivery |

| Sample | Sample available |

| Terminal/Housing Type | Customized |

| Wire | Customized |

Feature

It can simplify the assembly process of electronic products, easy to maintain, easy to upgrade, and improve the flexibility of design.

High-speed and digitized signal transmission, integration of various types of signal transmission, miniaturization of product volume, surface-mounted contact termination methods, module combination, and convenient plugging and unplugging.

Applications

Used for internal connection of various home appliances, test instruments, equipment, computers and network equipment.

Production process

1.Line cutting

The accuracy of the wire-opening process is directly related to the entire production schedule. Once an error occurs, especially if the wire-opening size is too short, it will lead to rework of all stations, which is time-consuming and labor-intensive and affects production efficiency.

2.Wear a sheath

3.Peeling

4.Riveting terminal

Determine the crimping parameters according to the terminal type required by the drawing, and make the crimping operation manual. If there are special requirements, it is necessary to indicate on the process document and train the operator.

5.Assemble the plastic shell

First of all, the pre-assembly process operation manual must be compiled. In order to improve the efficiency of the final assembly, a pre-installation station must be set for complex wiring harnesses. If the pre-assembled part is assembled too little or the wire path of the assembly is unreasonable, it will increase the workload of the general assembly personnel.

6.Test

7.Assembly

According to the assembly platen designed by the product development department, design tooling equipment, material box specifications and dimensions, and paste the numbers of all assembly sheaths and accessories on the material box to improve assembly efficiency.

8.Packaging and storage

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.