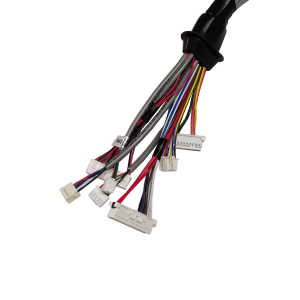

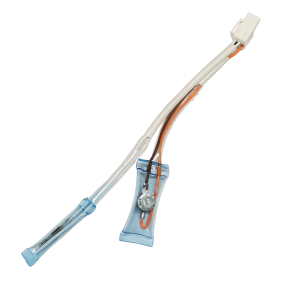

Customized OEM Wire Harness Assembly for Refrigerator/Fridge Parts

Product Parameter

| Use | Wire harness for refrigerator, freezer, ice machine |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Terminal | Molex 35745-0210, 35746-0210, 35747-0210 |

| Housing | Molex 35150-0610, 35180-0600 |

| Adhesive tape | Lead-free tape |

| Foams | 60*T0.8*L170 |

| Test | 100% test before delivery |

| Sample | Sample available |

| Terminal/Housing Type | Customized |

| Wire | Customized |

Applications

Spas, Washing machines, dryers, refrigerators, and other household appliances

Consumer and commercial electronics

Automotive equipment

Commercial and industrial machinery

Medical equipment and electronic devices

How the Custom Wire Harness Assembly Process Works

The wire harness assemblys we create here at Meridian are engineered to fit perfectly within their intended environment. That means making sure the design fits geometrically and within the specifications required of the system. Whether it’s for an industrial control system in a busy bottling facility or the OEM wire harnesses required in the automotive sector, the idea of “fit” is crucial in wire harness design.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.