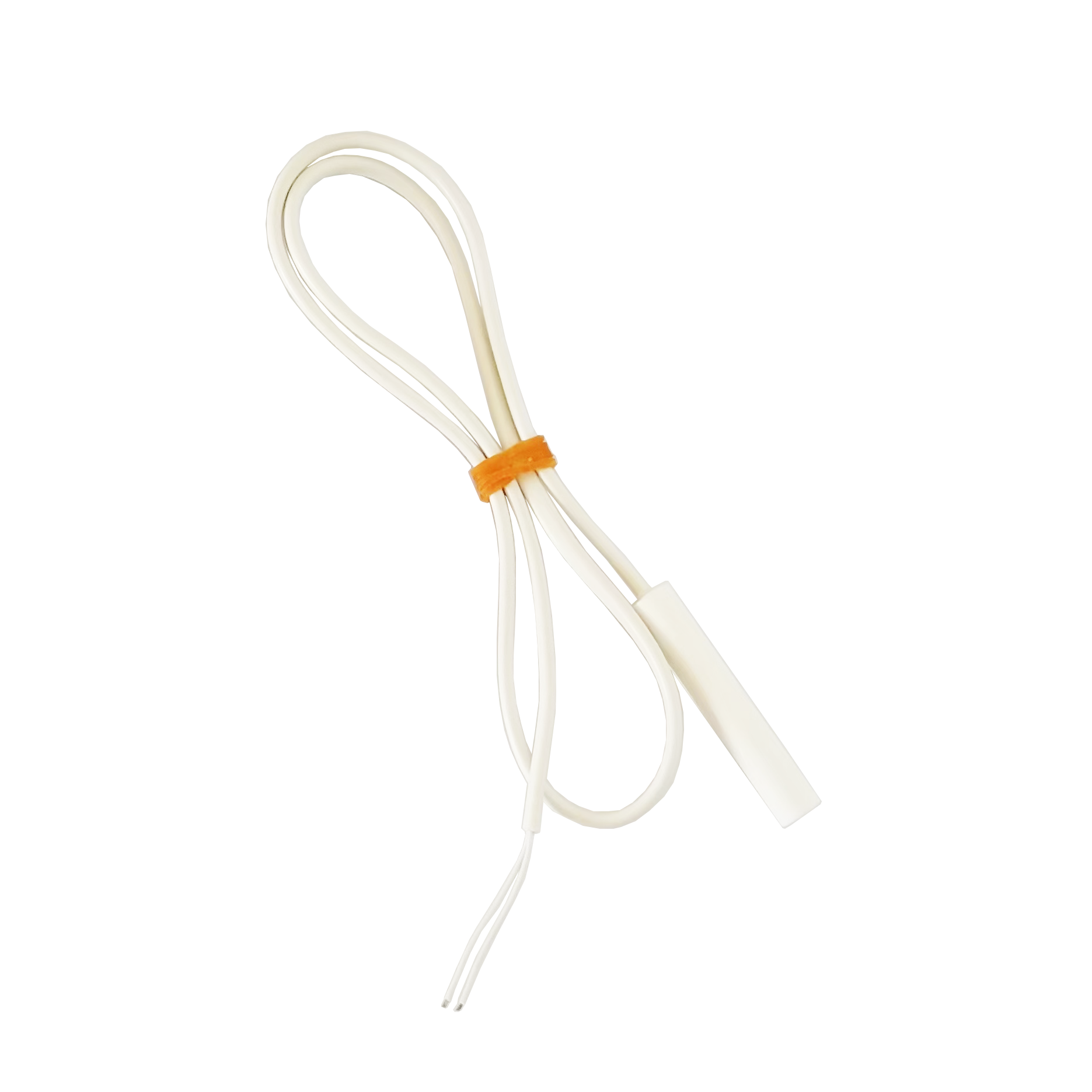

Customized NTC Temperature Sensor for Refrigerator Defrost Temp Sensor

Product Parameter

| Product Name | Customized NTC Temperature Sensor for Refrigerator Defrost Temp Sensor |

| Use | Refrigerator Defrost Control |

| Reset Type | Automatic |

| Probe Material | PBT/PVC |

| Operating Temperature | -40°C~150°C (dependent on wire rating) |

| Ohmic Resistance | 5K +/-2% to Temp of 25 deg C |

| Beta | (25C/85C) 3977 +/-1.5%(3918-4016k) |

| Electric Strength | 1250 VAC/60sec/0.1mA |

| Insulation Resistance | 500 VDC/60sec/100M W |

| Resistance Between Terminals | Less than 100m W |

| Extraction Force between Wire and Sensor Shell | 5Kgf/60s |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal/Housing type | Customized |

| Wire | Customized |

Applications

Typical Applications:

- Air conditioners - Refrigerators

- Freezers - Water Heaters

- Potable Water Heaters - Air Warmers

- Washers - Disinfection Cases

- Washing Machines - Driers

- Thermotanks - Electric iron

- Closestool - Rice cooker

- Microwave/Electricoven - Induction cooker

Features

- Wide variety of installation fixtures and probes are available to suit customer needs.

- Small size and fast response.

- Long-term stability and reliability

- Excellent tolerance and inter changeability

- Lead wires can be terminated with customer-specified terminals or connectors

Product Advantage

Our Customized NTC Temperature Sensor for Refrigerator Defrost Temp Sensor offers excellent reliability in a compact, cost-effective design. The sensor is also a proven performer for moisture protection and freeze-thaw cycling. Lead wires can be set to any length and color to match your requirements. The plastic shell can be made from Copper, Stainless Steal PBT, ABS, or most any material that you need for your application. The internal thermistor element can be selected to meet any resistance-temperature curve and tolerance.

Feature Advantage

There are different types of thermistors, most of which respond differently to changes in temperature. Thermistors are not linear and their response curves vary from type to type. Some thermistors have a near-linear temperature-resistance relationship, others have a sharp change in slope (sensitivity) at a specific characteristic temperature.

Craft Advantage

We operate additional cleavage for the wire and pipe parts to reduce the flow of epoxy resin along the line and reduce the height of the epoxy. Avoid gaps and breakage bending of wires during assembly.

Cleft area effectively reduce the gap at the bottom of the wire and reduce the immersion of water under long-term conditions.Increase the reliability of the product.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.