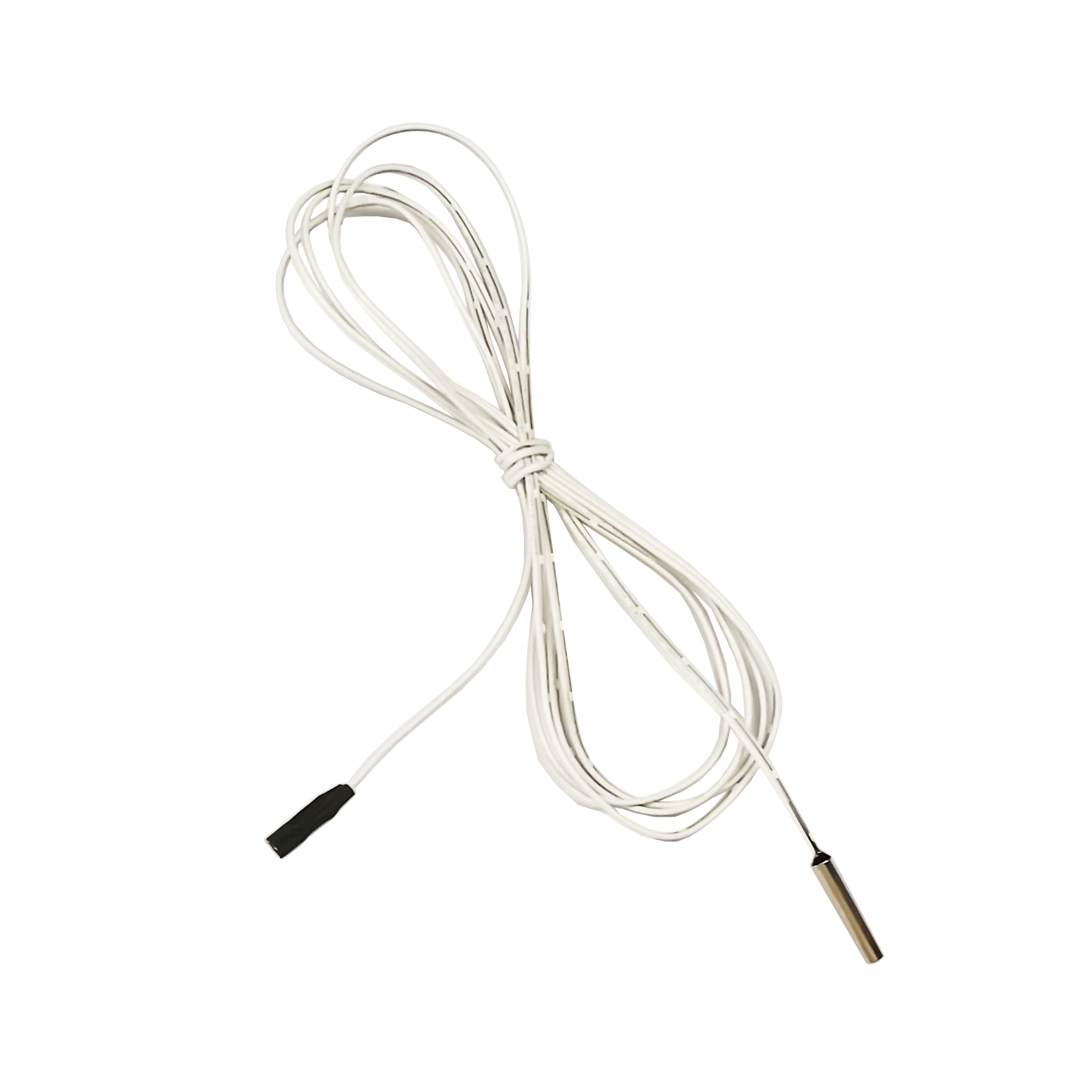

CQC Certified NTC Thermistor Refrigerator Defrost Temp Sensor Stainless Steel Shell

Product parameter

| Product Name | CQC Certified NTC Thermistor Refrigerator Defrost Temp Sensor Stainless Steel Shell |

| Use | Refrigerator Defrost Control |

| Reset Type | Automatic |

| Probe Material | PBT/PVC |

| Operating Temperature | -40°C~150°C (dependent on wire rating) |

| Ohmic Resistance | 5K +/-2% to Temp of 25 deg C |

| Beta | (25C/85C) 3977 +/-1.5%(3918-4016k) |

| Electric Strength | 1250 VAC/60sec/0.1mA |

| Insulation Resistance | 500 VDC/60sec/100M W |

| Resistance Between Terminals | Less than 100m W |

| Extraction Force between Wire and Sensor Shell | 5Kgf/60s |

| Approvals | UL/ TUV/ VDE/ CQC |

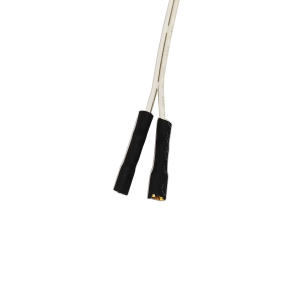

| Terminal/Housing type | Customized |

| Wire | Customized |

Applications

• Refrigerators

• White goods

• Freezers, deep-freezers

• Ice cube makers

• Counter drinks coolers

• Backbar and catering coolers

• Display fridges

Working Principle

NTC temperature sensor working principle is the same with the NTC thermistor, the principle is: the resistance value of the resistance with increasing temperature decreases rapidly. It is usually composed of 2 or 3 kinds of metal oxides, and in the high temperature furnace forging into a precision ceramic sintered body. The actual size is very flexible, they can be as small as .010 inches or very small diameter. The maximum size is almost unlimited, but usually applies for half an inch or less.

Feature

- Wide variety of installation fixtures and probes are available to suit customer needs.

- Small size and fast response.

- Long-term stability and reliability

- Excellent tolerance and inter changeability

- Lead wires can be terminated with customer-specified terminals or connectors

Craft Advantage

We operate additional cleavage for the wire and pipe parts to reduce the flow of epoxy resin along the line and reduce the height of the epoxy. Avoid gaps and breakage bending of wires during assembly.

Cleft area effectively reduce the gap at the bottom of the wire and reduce the immersion of water under long-term conditions.Increase the reliability of the product.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.