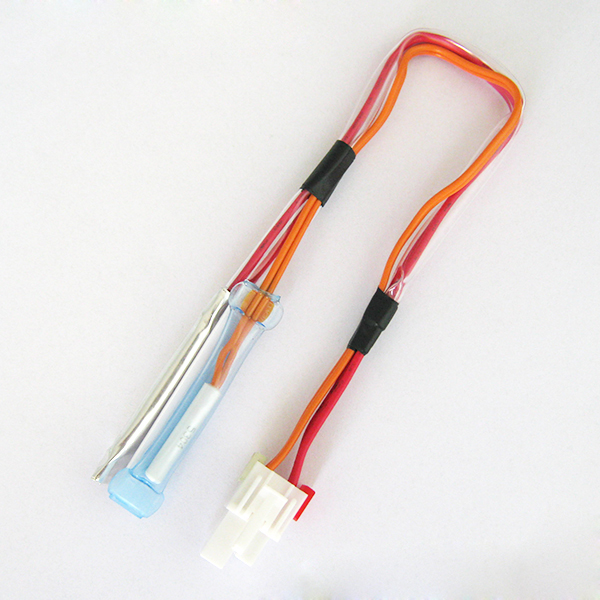

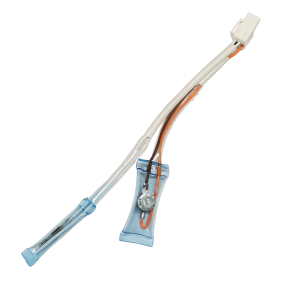

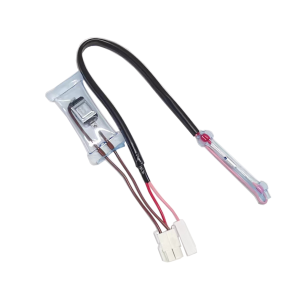

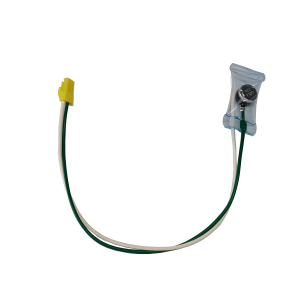

Cooling Heating Switch Thermostat NTC Sensor Assembly LG Refrigerator Parts HB-5Z

Product Parameter

| Product Name | Cooling Heating Switch Thermostat NTC Sensor Assembly LG Refrigerator Parts HB-5Z |

| Use | Refrigerator Defrost Control |

| Reset type | Automatic |

| Probe material | PBT/ABS |

| Operating Temperature | -40°C~150°C |

| Electric Strength | 1250 VAC/60sec/0.5mA |

| Insulation Resistance | 500VDC/60sec/100MW |

| Resistance Between Terminals | Less than 100mW |

| Extraction force between wire and sensor shell | 5Kgf/60s |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Air conditioners - Refrigerators

- Freezers - Water Heaters

- Potable Water Heaters - Air Warmers

- Washers - Disinfection Cases

- Washing Machines - Driers

- Thermotanks - Electric iron

- Closestool - Rice cooker

- Microwave/Electricoven - Induction cooker

Features

• Low profile

• Narrow differential

• Dual contacts for extra reliability

• Automatic reset

• Electrically insulated case

• Various terminal and lead wires options

• Standard +/5°C tolerance or optional +/-3°C

• Temperature range -20°C to 150°C

• Very economical applications

Feature Advantage

Wide variety of installation fixtures and probes are available to suit customer needs.

Small size and fast response.

Long-term stability and reliability

Excellent tolerance and inter changeability

Lead wires can be terminated with customer-specified terminals or connectors

Managing the Defrost Thermostat

There is an associated running cost with having the additional defrost thermostat system, which can be mitigated in several ways.

If the level of frost is low it is possible to defrost the evaporator during a compressor off cycle. This means the device isn’t actively cooling so the temperature will begin to rise toward ambient. As no additional heating element is required the running costs are therefore minimal, commonly just the cost of keeping the fan operating to help move the condensate away from the evaporator towards a drain, to remove moisture and reduce future frost build up.

If the refrigerator temperature setpoint is very low and simply turning the compressor off is insufficient to raise the temperature enough for the frost to melt then it is necessary to include a heating element in to the system. These systems will have a higher running cost than relying on the off cycle, but will remove larger frost deposits far more effectively which will improve overall system efficiency longer term.

In cases where a heater is present the most efficient way to defrost is when a specified variable that measures the level of frost reaches a setpoint. For an infrared system this would be when there is no frost tripping the sensor and for a temperature controller system it would be when the temperature of the evaporator has risen to a predefined temperature.

Finally there is the option of having timed defrost at regular intervals which last for an amount of time specified by the user. These intervals need to be long enough to remove the accumulated frost, but not so long as to as unnecessarily warm the environment.

This method is cheaper and easier to install and set up than solutions involving an additional sensor, however the timed element does not guarantee the same efficiency as the other methods and also requires greater input from an operator in terms of changing the settings to work out what the optimum length of time is for the defrost system to operate. As such over the lifetime of the defrost thermostat system the lower efficiency and higher running costs can outweigh the higher initial cost of a more complicated sensing system in particularly sensitive environments.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.