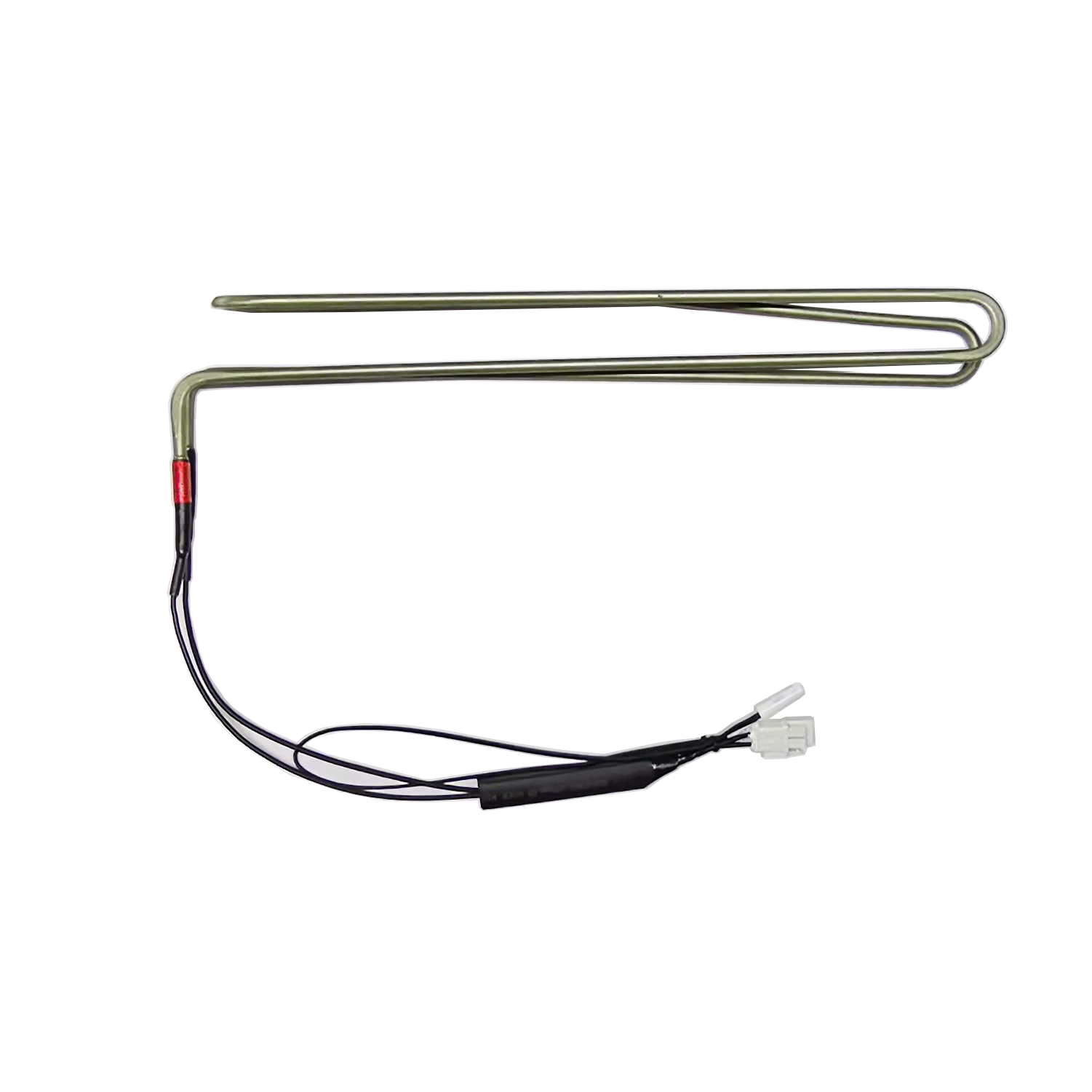

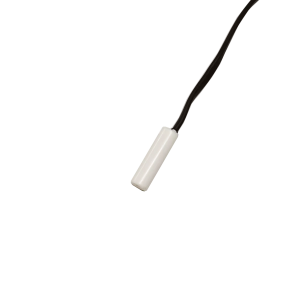

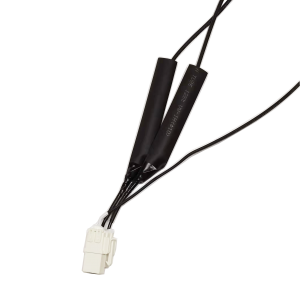

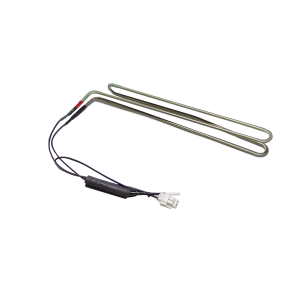

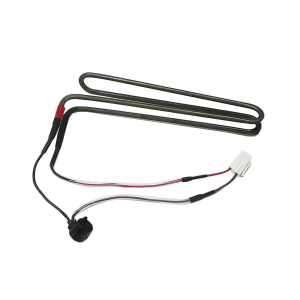

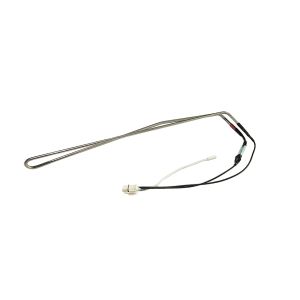

220V 200W Refrigerator Heating Element with Ntc Sensor BCD-451 Tubular Defrost Heater

Product Parameter

| Product Name | 220V 200W Refrigerator Heating Element with Ntc Sensor BCD-451 Tubular Defrost Heaterer |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

- Widely used for defrosting in refrigerators, deep freezers etc.

- These heaters can also be used in dry boxes, heaters and cookers and other middle temperature applications.

Product Structure

Stainless Steel Tube heating element uses steel pipe as heat carrier. Put heater wire component in Stainless Steel Tube to form different shape components.

Features

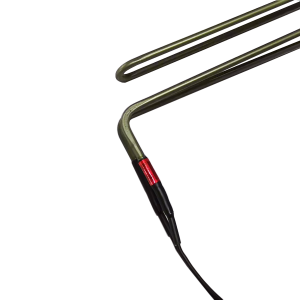

(1)Stainless steel cylinder, small volume, less occupation, easy to move, with strong corrosion resistance.

(2)The high temperature resistance wire is placed in the stainless steel tube, and the crystalline magnesium oxide powder with good insulation and thermal conductivity is tightly filled in the void part. The heat is transmitted to the metal tube through the heating function of the electric heating wire,thereby heating up. Fast thermal response, high temperature control precision, high comprehensive thermal efficiency.

(3)Thickened thermal insulation layer is used between the stainless steel liner and the stainless steel shell, which minimizes temperature loss, maintains temperature and saves electricity.

How to replace a refrigerator defrost heater

1.Locate your defrost heater. It can be located behind the back panel of the freezer section of your refrigerator, or under the floor of your refrigerator's freezer section. Defrost heaters are commonly located beneath a refrigerator's evaporator coils. You will have to remove any objects that are in your way such as the contents of the freezer, freezer shelves, icemaker parts, and the inside rear, back, or bottom panel.

2.The panel you need to remove may be held in place with either retainer clips or screws. Remove the screws or use a screwdriver to release the clips holding the panel in place. Some older refrigerators may require that you remove a plastic molding before you can gain access to the freezer floor. Exercise caution when removing the molding, as it does break fairly easily. You could try warming it with a warm, wet towel first.

3.Defrost heaters are available in one of three primary types: exposed metal rod, metal rod covered with aluminum tape, or a wire coil inside a glass tube. Each of these three types is tested in exactly the same way.

4.Before you can test your defrost heater, you have to remove it from your refrigerator. A defrost heater is connected by two wires, and the wires are connected with slip-on connectors. Firmly grasp these connectors and pull them off the terminals. You may need a pair of needle-nosed pliers to help you. Do not pull on the wires themselves.

5.In addition to the two wires, there may also be some clips or screws holding it in place. You will have to release any clips or remove any screws before the defrost heater can be removed. If your defrost heater has an outer glass tube, refraing from touching the glass with your bare fingers. It is possible for skin and/or oil from your fingers could cause the heater to burn hot. This could result in damage to your freezer and/or your heater. If you do happen to touch the glass with your bare fingers, clean it with rubbing alcohol and a clean cloth or paper towel.

6.Install the new defrost heater and reconnect its wires. Replace the access panel you may have had to remove. Restore power to your refrigerator.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.