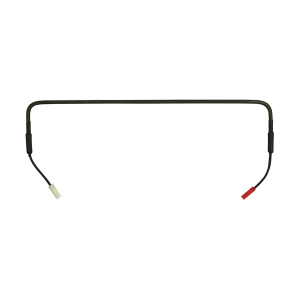

220V 160W Tubular Stainless Steel Heating Element for Refrigerator Defrost Heater BCD-236

Product Parameter

| Product Name | 220V 160W Tubular Stainless Steel Heating Element for Refrigerator Defrost Heater BCD-236 |

| Humidity State Insulation Resistance | ≥200MΩ |

| After Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Surface Load | ≤3.5W/cm2 |

| Operating Temperature | 150ºC(Maximum 300ºC) |

| Ambient temperature | -60°C ~ +85°C |

| Resistant voltage in water | 2,000V/min (normal water temperature) |

| Insulated resistance in water | 750MOhm |

| Use | Heating Element |

| Base material | Metal |

| Protection class | IP00 |

| Approvals | UL/ TUV/ VDE/ CQC |

| Terminal type | Customized |

| Cover/Bracket | Customized |

Applications

Typical Applications: the refrigerator will freeze and frost during the use process, so the refrigerator is generally equipped with a defrost heater.

- Wind-cooling refrigerator

- Cooler

- Air-conditioner

- Freezer

- Showcase

- Washing Machine

- Microwave Oven

- Pipe heater

- and some home appliance

Features

Defrost heater has the features such as the fine defrosting result, high electrical strength, nice insulating resistance, anti-corrosion and ageing, strong overload capacity, little current leakage, good stability and reliability, long service life, ect.

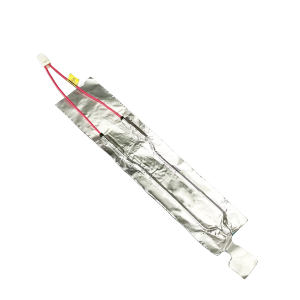

(1)Stainless steel cylinder, small volume, less occupation, easy to move, with strong corrosion resistance.

(2)The high temperature resistance wire is placed in the stainless steel tube, and the crystalline magnesium oxide powder with good insulation and thermal conductivity is tightly filled in the void part. The heat is transmitted to the metal tube through the heating function of the electric heating wire,thereby heating up. Fast thermal response, high temperature control precision, high comprehensive thermal efficiency.

(3)Thickened thermal insulation layer is used between the stainless steel liner and the stainless steel shell, which minimizes temperature loss, maintains temperature and saves electricity.

Product Advantage

- Custom cold sections

- Elements available in copper, incoloy or stainless steel

- Factory installed wire terminations

- Inline fusing

- Grounding wire welded to element sheath

- Single ended or double ended molded waterproof terminals

- Bimetal automatic limit control and/or fusible link molded in a waterproof mold for sheath temperature sensing

Production Process

A high temperature resistance wire is placed in the metal tube, and the crystalline magnesium oxide powder with good insulation and thermal conductivity is tightly filled in the gap, and the heat is transferred to the metal tube through the heating function of the heating wire, thereby heating up. The stainless steel cylinder is used, which is small in size, occupies less space, is easy to move, and has strong corrosion resistance. A thickened thermal insulation layer is used between the stainless steel inner tank and the stainless steel outer shell, which minimizes temperature loss, maintains temperature, and saves electricity.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our product has passed the CQC,UL,TUV certification and so on, has applied for patents accumulatively more than 32 projects and has obtained scientific research departments above the provincial and ministerial level more than 10 projects. Our company has also passed the ISO9001 and ISO14001 system certificated, and national intellectual property system certificated.

Our research and development and production capacity of the company’s mechanical and electronic temperature controllers have ranked in the forefront of the same industry in the country.